Customer Requirements of Grinding Process:

A tool manufacturer needed to efficiently process carbide end mills (D18mm × 36mm, 4 flutes) on a Walter Helitronic Power grinding machine, with a surface roughness requirement of ≤Ra0.2, while reducing dressing frequency to improve production efficiency.

Moresuperhard Efficiently-designed Solution

Moresuperhard Efficiently-designed Solution

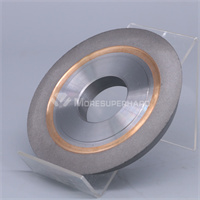

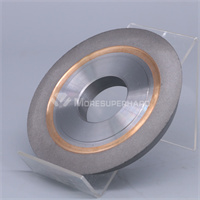

Moresuperhard Hybrid Bond diamond grinding

Moresuperhard Hybrid Bond diamond grinding wheel (model: 1V1 D100×T12×H20×X10) was used in combination with the Walter grinding machine's 33kW high power and 18m/s linear speed to achieve:

Single dressing enables the continuous processing of 82 tools, significantly reducing downtime

Coarse grinding feed rate of 100 mm/min and fine grinding feed rate of 40 mm/min, balancing efficiency and precision

Surface roughness consistently achieves Ra0.2, meeting high surface finish requirements

Technical Highlights

Hybrid Bond

Technical Highlights

Hybrid Bond Technology: Combines the advantages of resin and metal bonding agents, balancing wear resistance and cutting sharpness to extend wheel life.

High adaptability: Perfectly matches Walter Helitronic Power grinding machine parameters (speed 18 m/s, wheel specification 1V1).

Cost-effective: Ultra-long processing cycle of 82 pieces per dressing significantly reduces per-piece costs.

Customer Benefits:

Customer Benefits:

30% increase in production efficiency, reduced dressing time

Excellent surface consistency of tools, with a pass rate exceeding 98%

Extended grinding wheel lifespan, resulting in reduced overall costs

Application Areas of Moresuperhard Hybrid Bond diamond grinding wheel:

Batch grinding of precision tools such as carbide end mills, ball-nose mills, and step drills.

Contact us now to obtain your customized tool grinding solution!