In the realm of metalworking, achieving exceptional precision and efficiency in internal grinding operations is essential, especially when dealing with challenging materials like 440C stainless steel. In a recent customer case, our company collaborated with a British manufacturer to optimize their internal grinding process for 440C stainless steel components, leveraging the cutting-edge Resin CBN Internal Grinding Wheels.

Challenges When Processing 440C Stainless Steel:

The customer encountered significant challenges when grinding 440C stainless steel, known for its high hardness, wear resistance, and toughness. Conventional abrasive grinding wheels struggled to provide the desired cutting performance, often resulting in reduced precision, slow material removal, and compromised surface quality. The customer sought a reliable and efficient solution to address these grinding limitations.

Solution for Processing 440C Stainless Steel with Resin CBN Internal Grinding Wheels:

To overcome these challenges, our company introduced the advanced Resin CBN Internal Grinding Wheels, carefully engineered to cater specifically to the demands of grinding 440C stainless steel. The innovative combination of a resin bond system and CBN (Cubic Boron Nitride) abrasive grains promised exceptional cutting performance, improved precision, and enhanced efficiency.

Details of Customer Case of Processing 440C Stainless Steel with Resin CBN Internal Grinding Wheels:

Processed workpiece: 440C stainless steel (harder than ordinary stainless steel, better toughness than cemented carbide)

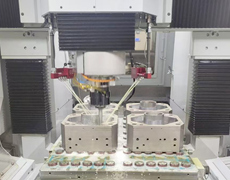

Grinder Model:

Studer S100 Grinder

.jpg)

Processing parameters: the spindle speed is up to 60,000 RPM, and the dressing spindle will use SG wheels with a speed between 5,000 and 22,000 RPM.

Grinding requirements: the precision reaches 16 wires, and the smoothness reaches 0.4 μm

Processing grinding wheel drawings:

.jpg) Grinding Results of Resin CBN Internal Grinding Wheels for 440C Stainless Steel:

Grinding Results of Resin CBN Internal Grinding Wheels for 440C Stainless Steel:

The implementation of Resin CBN Internal Grinding Wheels yielded remarkable results for the customer's internal grinding process on 440C stainless steel components. The cutting-edge technology behind the resin bond system and CBN abrasive grains delivered significant benefits in terms of precision and efficiency. The Resin CBN Internal Grinding Wheels demonstrated superior material removal rates, allowing for faster grinding cycles and increased productivity. The exceptional hardness and wear resistance of CBN abrasive grains ensured consistent cutting performance and extended wheel life, reducing the frequency of wheel replacements and associated downtime. Furthermore, the precise control and stability provided by the resin bond system led to enhanced dimensional accuracy, surface quality, and minimized workpiece damage during the grinding process. The unique bond characteristics efficiently dissipated heat, preventing thermal damage to the 440C stainless steel components, and maintaining their structural integrity.

Moresuperhard Summary:

The successful collaboration between our company and the manufacturer in utilizing Resin CBN Internal Grinding Wheels for 440C stainless steel highlighted the transformative potential of this cutting-edge abrasive technology. By unlocking precision, efficiency, and extended wheel life, the customer experienced improved productivity, reduced costs, and enhanced grinding performance. With a commitment to innovation and breakthrough solutions, our company continues to empower manufacturers in the metalworking industry to overcome grinding challenges, unlock new levels of precision, and achieve unparalleled results with challenging materials like 440C stainless steel.

---EDITOR: Jason Guo,Jackie Wang

---POST: Jackie Wang

.jpg)

.jpg)