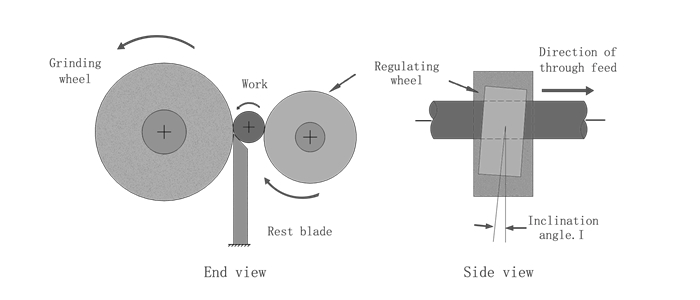

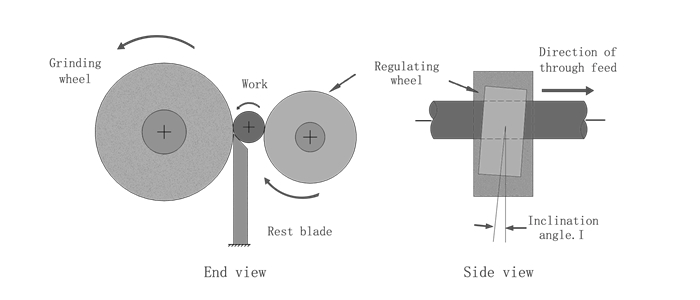

The grinding wheel and the smaller one is the pressure or regulating wheel.

The regulating wheel is a rubber-bonded abrasive having the frictional characteristics ta rotate the work at is own rotational speed. The speed of this wheel, which may be controlled, varies from 50 to 200 ft/min(0.25-1.02 m/s). Both wheels are rotating the same direction. The rest assists in supporting the work while it is being ground, being extended on both sides to direct the work travel to and from the wheels.

The axial movement of the work past the grinding wheel is obtained by tilting the wheel at a slight angle from horizontal.

In centerless grinding, the workpiece rotates between a grinding wheel and a regulating drive wheel. The work is supported from below by a fixed work-rest blade. The two basic modes of centerless grinding are "thru-feed" and "in-feed" or "plunge" mode. In the thru-feed mode, the work proceeds in the axial direction through the slowly narrowing gap between the grinding wheel and the regulating wheel. Work is advanced by the axial force exerted on it by the rotating surface of the regulating wheel. This is a highly productive form of grinding in that a number of workpieces can be ground simultaneously and in a continuous stream. The "infeed" mode is used for work with projecting heads that would prohibit "thru-feeding," the work is placed on the work-rest blade while one wheel is retracted and fed to an end stop. The wheel is then brought back, reducing the gap between the wheels, grinding the work.

Three types of grinding for centreless cylindrical grinding machines

- Pass-through centreless grinding. The workpiece is fed in the direction of the grinding wheel axis for grinding. The axial feed of the workpiece is achieved by adjusting the slight inclination of the guide wheel axis. Suitable for grinding long, thin cylindrical workpieces. Short shafts and bushings without a central bore, etc.

- Plunge-cut centreless grinding. The workpiece is supported in a certain position on the pallet with an axial positioning pivot point and is ground by plunging the grinding wheel or guide wheel. For grinding workpieces with shoulders or bosses, cones, spheres or other rotary workpieces.

- Pass-through/Plunge-cut centerless grinding is a combination of these two types of grinding. In addition, there is tangential feed grinding and end-feed grinding where workpieces with steps are moved in and out of the axial direction. Centreless cylindrical grinding machines are highly productive. They are mostly used for mass production and can be easily automated.