Application areas of honing

Honing technology came into being with the birth and development of automobiles. In order to improve the performance of engines and extend the life of automobiles, honing technology was invented. At present, honing technology has become one of the key manufacturing technologies in the automotive industry.Honing is the most important precision manufacturing technique for cylinder working surface. Honing technology not only can be used in automobile, motorcycle, tractor, crankshaft, cylinder manufacturing, and can be widely used in aircraft, missiles, tanks, tanks, artillery, ships, industrial sewing machine, air machine, hydraulic pneumatic, radar, radio and television equipment, machine tools, dies, brake oil pump, nozzle, bearings, engineering machinery, pipe and other manufacturing areas.

Modern honing techniques

Modern honing technologies such as flat top honing, extrusion honing, composite electrolytic honing, CNC honing, ultrasonic honing, ultrasonic honing and laser honing

1) CNC laser honing technology is a key technology for the engine manufacturing of modern automobiles, motorcycles, tractors, ships, etc., and belongs to the field of optical and mechanical integration technology.

2) Ultrasonic honing has many advantages, such as small honing force, low honing temperature, oil stone not easy to block, high processing efficiency, good processing quality, high wear resistance of parts sliding surface, etc. It can solve the problems of ordinary honing, especially the steel thin-walled cylinder liner substrate , Honing problems of tough materials such as aluminum alloy cylinder liners, chrome-plated steel thin-wall cylinder liners, cast iron hardened cylinder liners and ceramic engines.

Simple feed honing

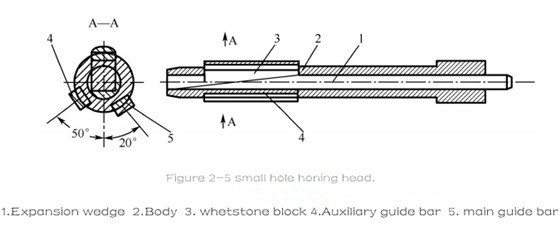

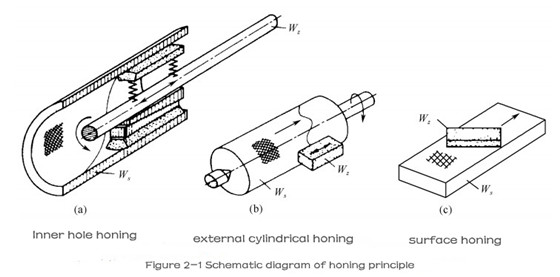

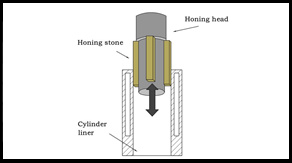

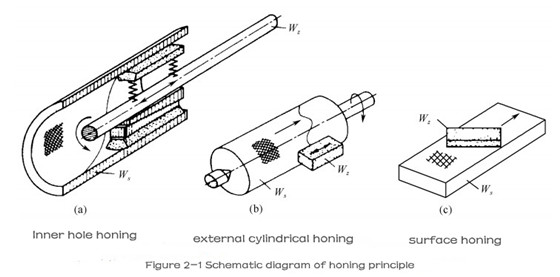

Single feed honing is a precision machining method that uses a set of whetstone assembled on the honing head, applies a certain pressure to the workpiece along the radial direction, and performs rotational and reciprocating motions. Honing can be used not only for precision machining of inner hole, but also for precision machining of outer circle, plane and surface.

Honing has the following characteristics:

Honing has the following characteristics:

(1) Good surface quality characteristics. Honing can get lower surface roughness, Ra can be 0.8 ~ 0.2 m, even lower than Ra 0.025 m. At the same time, the honing surface has even cross mesh, which is good for oil storage and lubrication .Hole shape error corrected by honing (a) ripple (b) taper (c) drum or convex

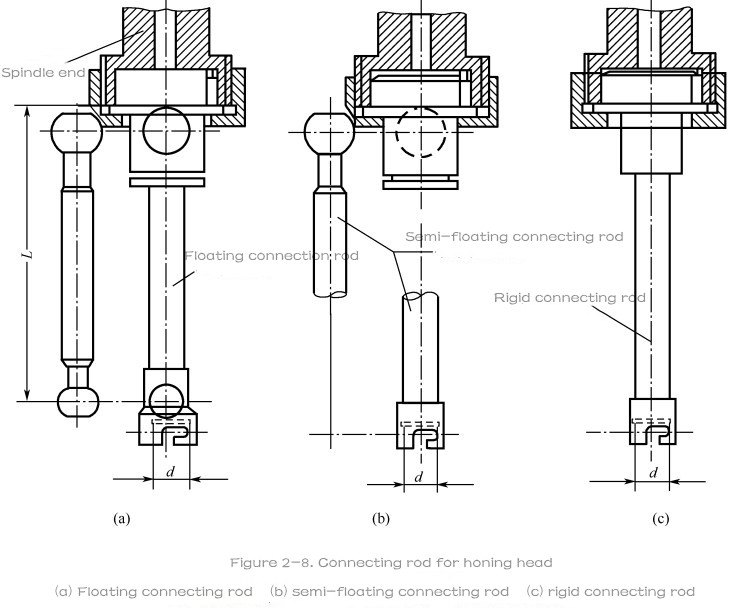

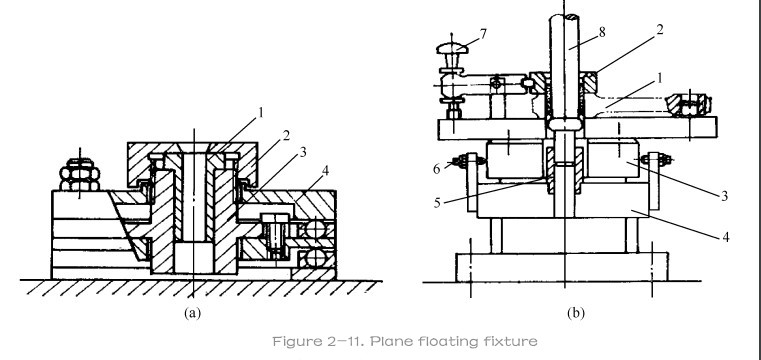

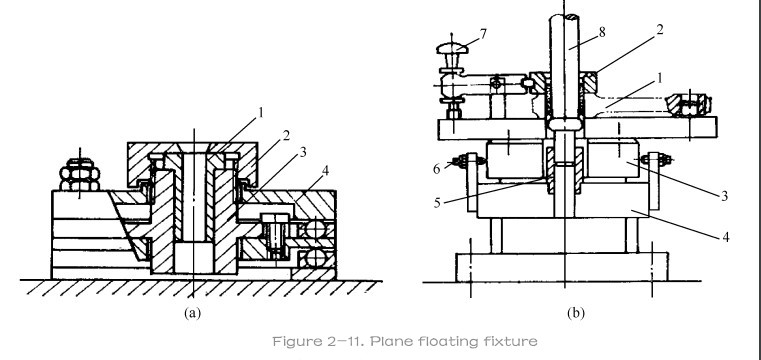

(2) High machining accuracy.The honing technology can not only achieve higher dimensional accuracy, but also correct holes (minor shape errors, such as roundness, cylindricity, and surface ripples, etc.). When honing holes, roundness and cylindricity can be up to 0.5 m, and axis straightness can be less than 1 m.Honing medium aperture, roundness up to 5 m, cylindricity up to 10 m.When honing short holes, the perpendicularity of the axis of the short hole and the end face can be improved if the honing head is rigidly connected with the flat floating fixture.Intermittent hole honing can improve coaxiality.

(3) High honing efficiency.Multiple honing stones or super hard abrasive stones can be used, and the reciprocating speed of honing head can also be increased to increase the cross Angle of the net, which can quickly remove the honing margin and hole shape error.Strong honing technique can also be applied to improve the honing efficiency effectively.

(4) The honing process is more economical.For thin wall holes and hard workpieces or hard workpieces, honing is easy to finish without complex equipment and equipment.

Honing clamp

Commonly used honing clamp can be fixed or floating. The floating type includes flat float (two degrees of freedom on the plane) and spherical float (two rotational degrees of freedom).Fixed types are used for honing large and heavy parts, while floating types are used for honing short holes, small holes and nesting parts.

| Honing clamp |

Equipped with the honing head connection type |

Scope of application |

Error of centralization(mm) |

| Fixed fixture |

Floating connection |

Large and medium holes, long holes in complex and irregular parts, Such as a variety of cylinder hole and cylinder sleeve hole, can get better results. |

<0.08 |

| Semi-floating connection |

Blind hole and short hole are processed with short whetstone, but the error caused by honing fixture and spindle is easy to be affected, Stable alignment accuracy is needed to ensure the honing quality |

<0.05 |

| Rigid connection |

Precision honing of small holes and workpiece holes with regular shape in mass production requires high accuracy in alignment. |

≤0.01 |

| Flat floating |

Rigid connection |

Honing short holes (L < D), such as connecting holes, gear holes, etc. The perpendicularity error between the axis and the end surface of the hole can be properly corrected, and the honing accuracy is high |

<0.02 |

| Semi-floating connection |

When the honing spindle is not too high and the float of the honing fixture is less than 1.0mm, the honing hole can get high precision |

<0.05 |

| Spherical floating fixture |

Rigid connection |

It is suitable for honing all kinds of small holes. In good alignment, holes with high straightness and uniform surface roughness can be obtained |

<0.02 |

| Semi-floating connection |

It is suitable for honing middle hole and small hole, and can obtain higher honing precision under longer whetstone or guiding condition |

<0.05 |

.png)