Characteristics of Vitrified CBN grinding wheel

Compared with other bonded CBN grinding wheels, vitrified bonded CBN grinding wheels have obvious advantages, which are explained as follows:

(1) Porosity. The pores on the surface of CBN grinding wheel with ceramic bond can provide space for chip tolerance and chip removal, which helps to avoid the blockage of grinding wheel. The pores on the surface of grinding wheel can also provide passage for coolant, reduce grinding temperature and reduce or avoid grinding burn.

(2) Heat resistance. Good heat resistance of ceramic bond makes full use of CBN abrasive and long service life of grinding wheel. The resin binder, on the other hand, does not hold the abrasive effectively at about 200℃.

(3) Self-sharpness. The CBN grinding wheel with ceramic bond has better self-sharpening and longer dressing interval, which reduces the dressing frequency.

(4) Processing effect. The surface integrity of workpiece grinding with CBN grinding wheel is good and the workpiece precision is high.

(5) Easy to repair. The CBN grinding wheel with ceramic bond is easy to be repaired, and the correction and sharpening can be completed at one time. The maintenance cost is low.

.jpg)

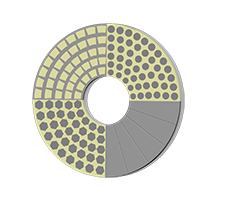

Application of vitrified bond CBN grinding disc in double face grinding

Double face grinding is a high efficient process for the end face of parts and components. It is widely used in the double face grinding of compressor valve, stator, rotor, bearing ring, blade and other workpiece. MoresuperhRD focuses on the development and production of ceramic bond CBN grinding wheel, and continues to optimize the formula design, preparation process and quality control of ceramic bond and CBN grinding tool. The product series includes inner hole grinding CBN grinding wheel, crankshaft GRINDING CBN grinding wheel, camshaft grinding CBN grinding wheel, ceramic bond CBN grinding wheel, etc. Multi-specification CBN grinding wheel with ceramic bond has been successfully applied in many fields. The ceramic bond CBN grinding disc developed by the company has high processing efficiency and good flatness and parallelism of the workpiece. It is suitable for grinding of high speed steel, powder metallurgy, wear-resistant cast iron, alloy cast iron, 20CrMo, 20CrMnTi, Cr12MOV and other materials.

With the continuous emergence and popularization of high-end grinding equipment, the application of ceramic bond CBN grinding wheel in forming grinding, high-efficiency grinding, high-precision grinding and other kinds of grinding will be more and more. At present, the ceramic bond CBN grinding wheel has been applied in the grinding of automobiles, bearings, machine tools, tools, air conditioners, refrigerators, engineering ceramics and many other fields.

It should be noted that due to the large contact area between the grinding wheel and the workpiece in double-face grinding, it is prone to rapid passivation of the grinding wheel, porosity blockage and burn, so attention should be paid to it during processing.

---EDITOR: Doris Hu

---POST: Doris Hu

.jpg)