Grinding ceramic and stainless steel femoral heads requires specialized grinding techniques and equipment due to the hardness and brittleness of ceramics and the toughness of stainless steel.

.jpg)

Here is a general overview of the grinding processes involved:

Preparing the Grinding Equipment: Ensure that the grinding machine and tools are clean and in good condition before starting the grinding process. This helps prevent contamination and ensures consistent results.

Choose the Right Grinding Wheel: Select a grinding wheel specifically designed for grinding ceramics and stainless steel. Diamond or cubic boron nitride (CBN) grinding wheels are commonly used for this purpose due to their hardness and abrasion resistance.

Set up the Grinding Machine: Adjust the settings of the grinding machine according to the manufacturer's instructions. This includes setting the speed, feed rate, and depth of cut to ensure optimal grinding conditions for both ceramic and stainless steel materials.

Secure the Workpiece: Use appropriate fixtures or clamps to securely hold the femoral head in place during grinding. This prevents movement or vibration that can affect the accuracy and quality of the grinding process.

Grinding the Ceramic Femoral Head: Start by grinding the ceramic portion of the femoral head using the selected grinding wheel. The process may involve rough grinding to remove excess material and create the desired shape, followed by fine grinding to achieve the desired surface finish.

Grinding the Stainless Steel Femoral Head: Once the ceramic portion is ground, switch to a different grinding wheel suitable for grinding stainless steel. Proceed with grinding the stainless steel portion of the femoral head, ensuring consistent pressure and movement to maintain even material removal and surface finish.

Cooling and Lubrication: To prevent overheating and damage to the femoral head or grinding wheel, use an appropriate coolant or lubricant during the grinding process. This helps dissipate heat and provides lubrication for smoother grinding.

Quality Control and Inspection: Regularly inspect the femoral head during the grinding process to ensure the desired dimensions, surface finish, and geometrical accuracy are achieved. Use measuring instruments such as calipers or micrometers to verify the results.

Post-Grinding Processes: Depending on the specific requirements, additional processes such as polishing, deburring, or cleaning may be necessary after grinding to achieve the final desired surface finish and remove any burrs or contaminants.

It is important to note that grinding ceramic and stainless steel materials requires expertise and caution due to their different properties. It is highly recommended to consult with experienced professionals or manufacturers' guidelines for specific instructions and safety precautions when performing these grinding operations.

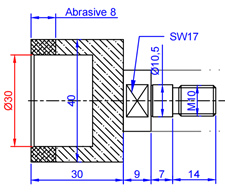

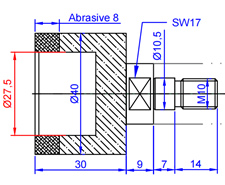

Moresuperhard's Grinding Solution for Ceramic and Stainless Steel Femoral Heads:

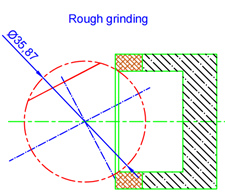

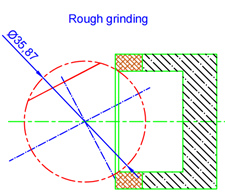

1. Rough grinding

Grinder: Studer

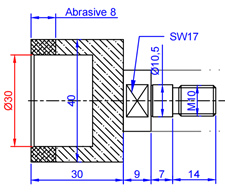

Wheel: Diamond wheel, vitrified bond, dressing possible

Removal stock Ø3.8,

Ra>0.4

Material Al2O3, Hardnenn HV 1400-1700

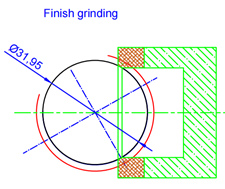

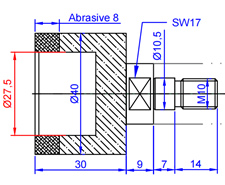

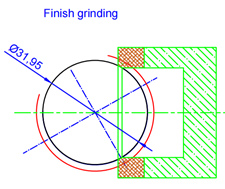

2. Finish grinding:

Grinder: Studer

Wheel: Diamond wheel, vitrified bond, dressing possible

Material Al2O3, Hardnenn HV 1400-1700

Removal stock Ø0.1mm,

Ra <0.1

Moresuperhard's Vitrified Diamond Grinding Wheels for Ceramic and Stainless Steel Femoral Heads:

These high-quality grinding wheels are designed to deliver superior precision, surface finish, and material removal rates. The vitrified diamond grinding wheels are made using a unique bonding process that involves heating a mixture of diamond abrasive grains, ceramic bonds, and metal powders. This creates a dense and uniform structure that ensures consistent grinding performance and long wheel life.

Moresuperhard's vitrified diamond grinding wheels for ceramic and stainless steel femoral heads are available in various sizes, grits, and concentrations to suit different grinding requirements. They can be used for both rough and fine grinding operations, delivering excellent results with minimal surface damage or deformation.

---EDITOR: Alan Wang,Jackie Wang

---POST: Jackie Wang

.jpg)