Introduction of Optical Profile Grinding Machine

.jpg) Optical Profile Grinding Machine

Optical Profile Grinding Machine is a kind of high-precision CNC grinding machine tool, which is mainly used for processing components with complex curved surface structure and high requirements for form and position accuracy, such as optical lens, optical prism, optical components, etc. It can realize optical twinning, form and position tolerance and surface roughness control of optical parts. It can realize optical profile, form and position tolerance and surface roughness control of optical parts, and become one of the indispensable equipments in modern optical processing industry.

The working principle of Optical Profile Grinding Machine

1. Principle of Optical Profile Grinding Machine

Optical twinning is a method commonly used in the processing of optical parts, which refers to the use of a machine tool to process a pair of symmetrical parts, so that they have the same shape, surface and position. Optical Twin Grinding Machine realizes optical twinning machining of optical parts by controlling the workpiece with precise three-dimensional trajectory and controlling the grinding tool.

2. Principle of surface machining

Parts with complex surface structures often require complex surface machining, and the light curvature grinder can perform three-dimensional surface machining on the workpiece through the rotation and movement of the machining tool. The workpiece is placed on the table, the rotation and movement of the table is controlled by the mechanical transmission system, and the position and attitude of the grinding head is controlled at the same time, so as to process the workpiece in accordance with the predetermined grinding path, and ultimately form the required complex surface structure.

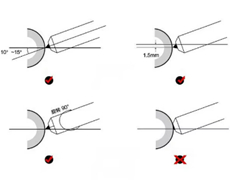

3. Principle of Optical Profile Grinding Machine grinding process

The main grinding tool used in the Optical Profile Grinding Machine is the grinding wheel, through which the surface of the workpiece is ground. The grinding process usually consists of three parts: grinding force, abrasive material and grinding heat. The grinding force comes from the friction between the grinding head and the surface of the workpiece, the abrasive is the material used to grind the surface of the workpiece, and the grinding heat is the heat generated during the grinding process.

The applications of Optical Profile Grinding Machine

.jpg)

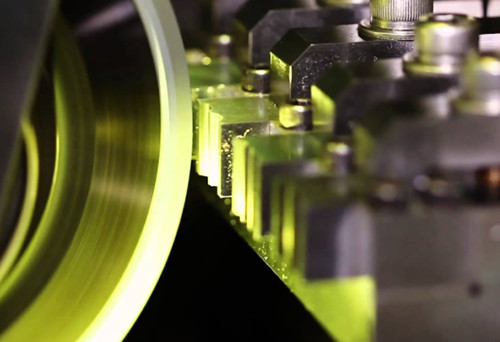

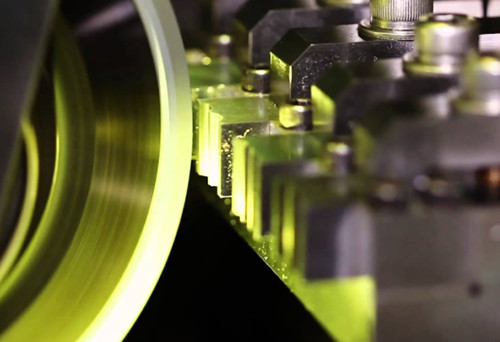

Optical Profile grinding machine can be widely used in optics, aerospace, instrumentation, precision instruments and other industries. For example, in the optical industry, Optical Profile Grinding Machine can be used to produce precision optical lenses, convex lenses, cylindrical lenses, prisms and other optical components. In the aerospace industry, Optical Profile Grinding Machines can be used to process precision structures of aerospace components, such as gyroscopes, inertial navigation devices and other high-precision parts.

Optical Profile Grinding Wheel

.jpg)

► Application: precise grinding mould and die, punch pin, optical grinding and form grinding cutting tool ( such as end mill and reamer) and precise instrument

► Model: 3A1, 14K1, 1B9

► Bonded: resin bond & metal bond

►

Optical Profile Grinder: Amada, Waida, Wasion, Moresuperhard, etc.

.jpg)

.jpg)

.jpg)