What does dressing mean?

Dressing a grinding wheel means reshaping its surface to restore its cutting performance or to change its surface characteristics.

In the case of a diamond grinding wheel, diamond dressing tools are used to resurface and clean off the accumulated grit and metal chips that clog the diamond particles. This process is called truing, which involves removing the worn-out surface of the grinding wheel to expose new diamond particles for efficient grinding. Truing can be done using a diamond dresser, a single-point tool, or a rotary diamond dresser.

Diamond dressing is a critical process as it ensures the optimal performance and longevity of the grinding wheel. The frequency of dressing depends on several factors such as the material being ground, grinding conditions, and the wheel wear rate. It is essential to ensure that the dressing process is properly carried out to avoid damaging the wheel or reducing its lifespan.

What are the different dressing methods of grinding wheel?

At present, the dressing methods of superabrasive grinding wheels can be divided into three categories: the first category is a mechanical dressing represented by abrasive block dressing, parallel wheel dressing, and cup wheel dressing; the second category is a special dressing method represented by electrical discharge dressing, electrolytic in-process dressing, and pulsed laser dressing; the third category refers to a combination dressing that combines several dressing methods to complement each other, such as mechanical-laser combination dressing, mechanical-chemical combination dressing and ultrasonic assisted dressing.

What is the process of wheel dressing?

The process of wheel dressing involves reshaping and cleaning the surface of a grinding wheel to restore its performance or change its surface characteristics. The method used to dress the wheel will depend on factors such as the type of wheel, material being ground, and desired surface finish. Here is a general overview of the wheel dressing process:

Choose the right dressing tool: Select a dressing tool that is appropriate for the type of wheel being dressed and the desired surface finish. Popular options include diamond dressers, rotary diamond dressers, single-point diamond tools, and dressing sticks.

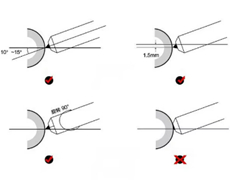

Mount the dressing tool: The dressing tool should be mounted securely in a tool holder or dressing fixture. Make sure the tool is positioned correctly so that it can contact the grinding wheel at the appropriate angle.

Set the grinding wheel speed: The grinding wheel should be rotating at a slow speed (usually around 100 RPM) during the dressing process.

Position the dressing tool: Bring the dressing tool into contact with the grinding wheel at a slight angle and apply moderate pressure to ensure maximum contact. Move the dressing tool back and forth across the surface of the wheel, keeping the pressure and speed consistent until the desired shape and surface finish is achieved.

Clean the wheel: After dressing, clean the grinding wheel to remove any debris or metal particles that may have accumulated on the surface.

Recheck wheel balance: It may be necessary to remount the grinding wheel and check for balance before resuming use.

Repeat as necessary: Depending on the type of grinding operation, it may be necessary to dress the wheel after a certain amount of use to maintain optimal performance.

Overall, wheel dressing is an essential process that helps to ensure the efficient and precise performance of grinding wheels. By following best practices, such as careful selection of dressing tools and maintaining consistent pressure and speed during the dressing process, it is possible to achieve the desired surface finish and extend the life of the grinding wheel.

It's important to note that the dressing process may vary depending on the specific grinding wheel and equipment being used. Always consult the manufacturer's instructions for specific guidelines on how to dress your particular wheel.

Moresuperhard is a leading manufacturer of diamond and CBN grinding tools including diamond grinding wheels, CBN grinding wheels, and dressing tools. We offer a range of high-quality dressing tools for diamond and CBN grinding wheels, designed to ensure the optimal dressing performance and longevity of the wheel.

Moresuperhard's diamond dressing tools include

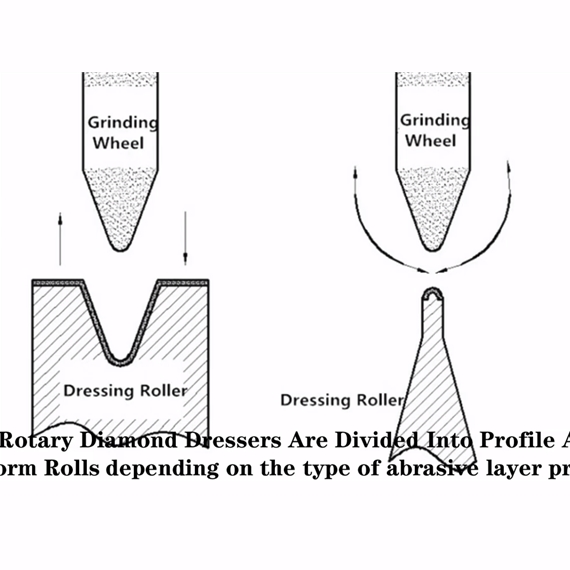

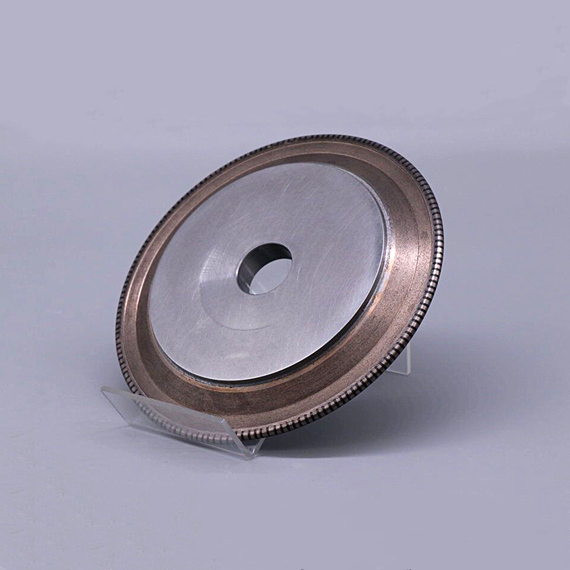

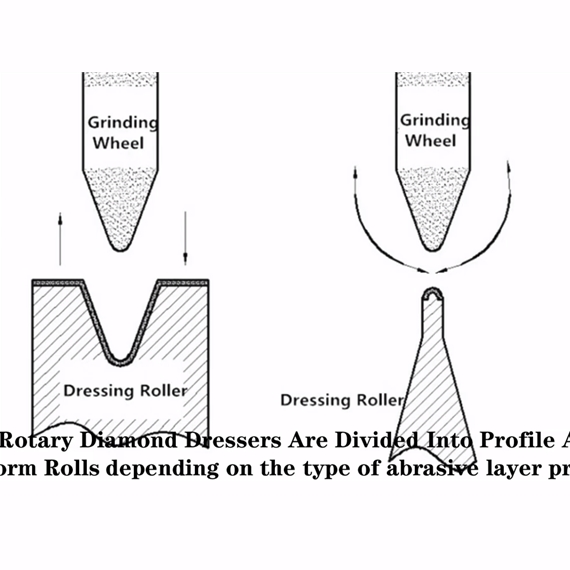

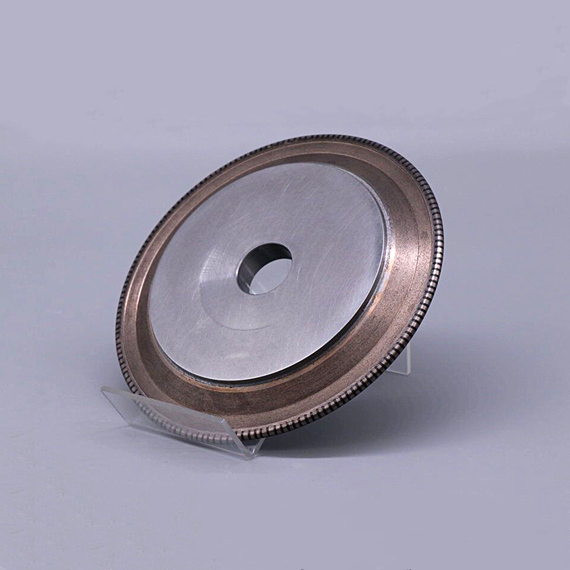

rotary diamond dressers, single-point diamond dressers, and diamond dressing rolls. The rotary diamond dresser is a popular choice for dressing large grinding wheels as it can cover a larger area and maintain consistency in the wheel's profile. The single-point diamond dresser is ideal for dressing smaller grinding wheels and producing a finer surface finish. Diamond dressing rolls are used for continuous dressing of diamond grinding wheels and are suitable for high-volume grinding operations.

For CBN grinding wheels, Moresuperhard offers high-quality CBN dressing discs that provide excellent dressing performance. The CBN dressing disc is ideal for high-speed grinding operations and can dress the wheel continuously without the need for frequent repositioning.

Overall, Moresuperhard's dressing tools are manufactured to the highest quality standards and are designed to provide optimal performance, precision, and consistency for a wide range of grinding applications.