Vitrified Superhard Double Face Grinding Discs: Vitrified Diamond Grinding Discs & Vitrified CBN Grinding Discs

Double Face Grinding (DDG), a grinding process for efficient machining of the end faces of parts, uses two relatively placed grinding wheels to simultaneously grind both end faces of the workpiece, usually one grinding can ensure equal cutting allowance on both sides.

-The color of diamond is yellowish and the color of CBN is blackish. The corresponding glue is black (with graphite) and yellow (original color).

-Regarding the substrate, steel and cast iron are the main materials. The substrate should be recycled at least 50 times. Commonly used 600-700 put 5 vernier wheels (fixed workpiece).

Grinding characteristics of double endface grinding disk

1. High grinding efficiency

2. High wear resistance

3. High grinding force, low grinding temperature

4. High precision of the ground workpiece, good surface quality, and good flatness of the workpiece.

Parameters of double endface grinding disk

Grinding disk diameter: 600mm-1200mm

Hole diameter: 200mm-400mm

Substrate thickness: 50mm-100mm

Abrasive layer thickness: 5mm-10mm

Grit size: #80 - #1500

Hardness: 50-100

Furnace sintering temperature: 720°

Normal rotating speed of grinding disk 30-60 rpm

Workpiece finish Ra0.1μm-Ra1.2μm

Grinding disk flatness 0.001mm-0.004mm, parallelism ≤ 0.002mm, isometric ≤ 0.002mm

Material of processed workpiece

Iron-based powder metallurgy, cast iron, bearing steel, cemented carbide, high-speed steel, ceramics, silicon nitride, PPS plastic and so on.

Application areas of grinding disk

- Automobile. Engine parts, bearings, transmission gears, stator, rotor, vane of steering pump, oil pump nozzle parts - Air conditioning. Compressor slide, compressor spacer, piston, valve plate

- Cutting Tools. Carbide inserts, PCD/PCBN cutters

- Ceramic Materials. Ceramic spools, zirconia-alumina ceramic rings.

- High Precision Bearing

- Seals, Piston Rings

- Aerospace. Hydraulic components Pneumatic components, hydraulic motor components

- Measuring tools, molds

- Gemstones, monocrystalline silicon wafers

- Magnetic materials

Matching double end grinding machine

Grinding cases of Double Grinding Wheels

Workpiece: Alumina ceramic seal

Size of workpiece: OD22*ID17 mm*T4.5mm

Purity: High alumina with 92% purity.

Hardness:1150HV

Removal allowance: 0.2mm

Number of workpieces per disk: 150

Double face grinding machine model: Speedfam DSM 9B-5FH

Flatness of workpiece after grinding: 0.0003mm

Parallelism of workpiece after grinding: 0.001mm

Surface finish after grinding: mirror surface

Grinding pressure: 150 GMs/CM2

Lower disk speed: RPM 70

Upper disk speed: RPM 35

Rotating speed of sun wheel: RPM 25

Number of cycles: 28

Density g/cm³ >7.0 (tooth >7.1)

Surface hardness HRB 70-95

P0.1 Yield strength MPa >370

Tensile strength MPa >460

Modulus of elasticity MPa 130000

Requirements for finish RZ6.3

Speed 500-600

Wet grinding: water from the top, overflow from the bottom

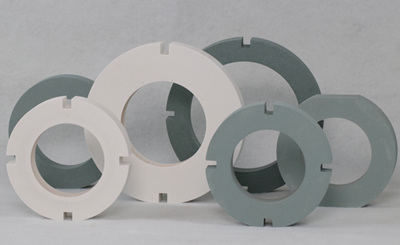

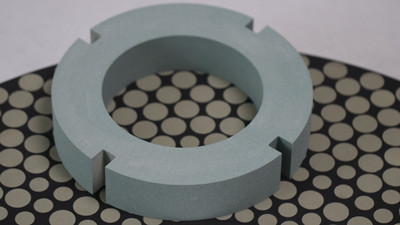

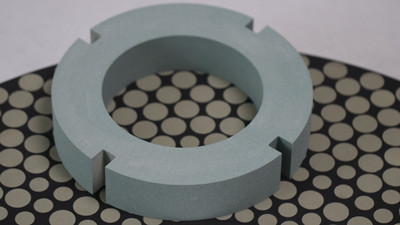

Ceramic double-face grinding disk dressing ring

White corundum (WA) dressing ring

Green Silicon Carbide (GC) Dressing Ring

Features of grinding disc dressing wheels

1. short dressing time for open edge dressing

2. Parallelism of open edge dressing can reach 0.02mm.

3. good sharpness of grinding disk after open edge dressing

4. more workpieces are ground after open flute dressing, and the frequency of dressing is reduced.

The general specifications are 205mm, 280mm, 330mm O.D., 30-60mm thickness, etc. Generally, 700 disks with 205mm O.D. dressing ring bore 127 mm; 860-1050mm disks with 280mm O.D. dressing ring bore 220 mm, and specification disks with 330mm O.D. dressing ring. Use 3 or 4 pieces for one set.

Trimming ring specifications:

gc/wa 205*40*127

gc/wa 205*60*127

GC/WA 228*40*127

gc/wa 230*40*127

GC/WA 280*40*200

GC/WA 280*60*200

GC/WA 330*40*200

GC/WA 330*60*200

Granularity: 100#-320#

Dressing ring size, thickness and grit can be customized according to customer's specific equipment and working conditions.

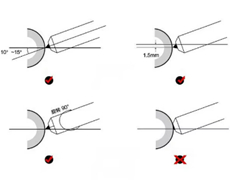

How to dress double end grinding disk on double end grinding machine?

1. Firstly, lift up the upper grinding disk, remove the upper grinding disk, and then the workers take out the workpieces and planetary wheels from the grinding disk.

2. Carefully clean the small amount of particles on the disc to avoid scratching the disc (grinding wheel); when cleaning the disc, turn on the rotation of the lower disc and then use the rotating speed to shake off the impurity particles left on the disc, and pour in the cleaning liquid together with the grinding disc when shaking the wheel.

3. Put in the planetary wheel, and then put the dressing ring into the planetary wheel, let the planetary wheel drive the dressing ring to correct the grinding disk (grinding wheel), correcting a roughly 15s-3min or so (we recommend that the new disk on the machine to repair for 1 minute, after normal use, each time to repair the whole open edge for 15 seconds can be, but the specific parameters of the repair and adjustment according to the customer's actual use of the situation).