The design of a grinding wheel plays a crucial role in optimizing the performance and accuracy of the grinding machine. In this article, we explore the case of a customer seeking to improve the body design of their electroplated CBN grinding wheel. The objective was to address the issue of excessive weight caused by the wide substrate, which negatively impacted the accuracy of the grinding machine spindle during the machining process. Through the innovative thinking and expertise of our senior engineers, an effective solution was developed to achieve a balance between weight reduction and machining effectiveness.

Understanding the Challenge of Electroplated CBN Grinding Wheel Body Design Improvement:

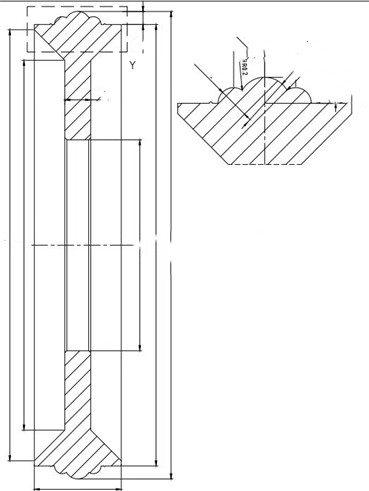

The customer's requirement was to grind silicon carbide with iron plates on both sides using an electroplated CBN grinding wheel. However, their initial wheel design featured a body width equal to that of the workpiece. As a result, the substrate’s weight exceeded 100 kilograms, resulting in significant strain on the grinding machine spindle and adversely affecting the machining accuracy. This challenge necessitated a novel approach to reduce the substrate weight while ensuring efficient grinding performance.

Moresuperhard Engineering Solution for Electroplated CBN Grinding Wheel Body Design Improvement:

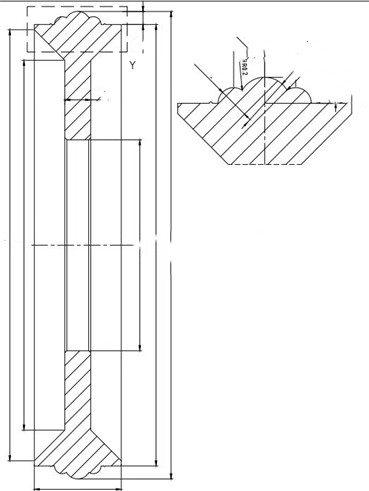

Our team of senior engineers embarked on a comprehensive analysis to address the issue of excessive substrate weight. After careful consideration and brainstorming sessions, they devised an innovative solution that involved narrowing the width of the grinding wheel’s body while maintaining optimal machining effectiveness.

Optimal Design Parameters:

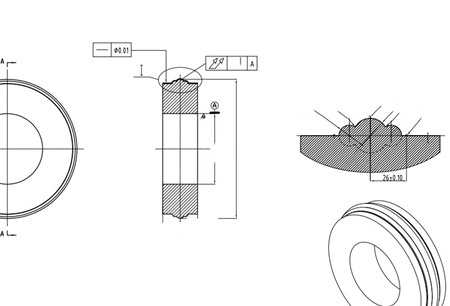

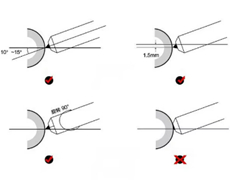

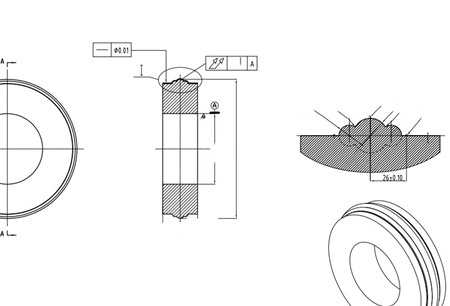

The senior engineers meticulously examined the requirements for grinding silicon carbide with iron plates on both sides. By applying their expertise, they determined the minimum necessary width for the substrate while still achieving the desired grinding results. This optimization process led to a narrower grinding wheel body design.

Improved Material Selection:

The choice of materials played a crucial role in reducing the weight of the grinding wheel body. Our engineers selected lightweight yet robust materials that maintained the structural integrity of the wheel while significantly reducing its overall weight. This careful material selection contributed to the successful weight reduction of the substrate.

Enhanced Machining Effectiveness:

While focusing on weight reduction, it was essential to ensure that the modified grinding wheel design maintained its effectiveness in the grinding process. Our senior engineers conducted thorough simulations and experimental tests to validate the performance of the narrowed grinding wheel body. Through iterative refinements, they ensured that the revised design retained its ability to achieve accurate and efficient grinding results.

Detailes of Electroplated CBN Grinding Wheel Body Design Improvement:

Processing workpiece: silicon carbide in the middle, iron on both sides.

Results and Benefits Electroplated CBN Grinding Wheel Body Design Improvement:

The improved electroplated CBN grinding wheel body design provided substantial advantages for the customer:

1. Weight Reduction: By narrowing the substrate width, the weight of the grinding wheel body was dramatically reduced from over 100 kilograms to less than 10 kilograms. This solved the problem of excess weight burdening the grinding machine spindle, resulting in improved machining accuracy.

2. Enhanced Machining Precision: The innovative design maintained the wheel’s effectiveness, allowing it to produce precise and consistent grinding results. The reduced weight minimized strain on the grinding machine spindle, resulting in enhanced accuracy during the machining process.

3. Increased Operational Efficiency: With the optimized body design, the customer experienced improved operational efficiency as the lighter grinding wheel facilitated faster setup and improved handling. This led to reduced downtime and increased productivity.

Moresuperhard Summary:

The successful improvement of the electroplated CBN grinding wheel body design exemplifies the importance of innovative thinking and expertise in addressing machining challenges. Through the knowledge and experience of our senior engineers, our customer achieved a significant reduction in weight without compromising machining effectiveness. By implementing this design improvement, the customer experienced enhanced accuracy, improved operational efficiency, and increased overall productivity. Trust in our engineering solutions to optimize your grinding processes and unlock new levels of efficiency and precision.

---EDITOR: Jim Jiao,Jackie Wang

---POST: Jackie Wang