We recently had a customer who used our Vitrified CBN Wheels for Air-conditioner Compressor Cylinder in their manufacturing process. The customer, a leading manufacturer of air-conditioning equipment, was experiencing issues with their existing grinding wheels, which were unable to meet their required levels of precision and surface finish. This affected the overall quality of their air-conditioner compressor cylinders, leading to product defects and increased production costs.

After consultation with our technical team, the customer decided to switch to our Vitrified CBN Wheels for Air-conditioner Compressor Cylinder. These wheels are specifically designed for high-speed grinding of compressor cylinders, offering exceptional hardness and thermal stability, and high precision and efficiency.

After implementing our Vitrified CBN Wheels, the customer saw significant improvements in both the quality and efficiency of their manufacturing process. The CBN wheels were able to remove material faster and more accurately, resulting in a significantly improved surface finish on the compressor cylinders. As a result, the customer’s production costs were reduced, and the overall quality of their air-conditioning equipment improved, leading to greater customer satisfaction.

Let's learn more about the specific processing content! The detail as follows:

1. Processing Machine:

Brand: Toyo

Machine Speed: 20000-25000RPM

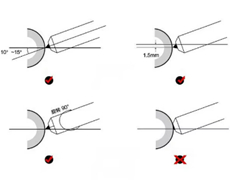

Dressing Method: Diamond rotary dresser

2. Information of Workpiece:

Name: Compressor cylinder

Material: FC250

Surface Ra request: Ra ≤0.3

3. Grinding Detals:

3. Grinding Detals:

Grindind wheels Bond :

Vitrified bond CBN wheel

Size: D33.5xM16

Grit: 140/170

Hardness: M

4. Grinding Parameters:

4. Grinding Parameters:

Allowance:0.2-0.3mm

Step: Rough grinding/Finish grinding/Polishing

Grinding time: 30ec/workpiece

Dressing cycle:110 - 130 pieces/dressing

Moresuperhard Summary:

Vitrified CBN wheels are widely used for machining air-conditioner compressor cylinders because of their exceptional hardness and thermal stability. They are able to grind and shape the hardest materials, including hardened steel and cast iron, with great precision and efficiency.

Specific Information Regarding Vitrified CBN Wheels for Air-conditioner Compressor Cylinders:

1. Size: The wheels typically range from 350mm to 450mm in diameter, with a thickness of 6mm to 10mm.

2. Bond: The bond refers to the material that holds the abrasive grains together in the wheel. Vitrified CBN wheels are composed of ceramic bonds that are fired at high temperatures to create a very hard and stable structure.

3. Abrasive: The abrasive material used in vitrified CBN wheels is cubic boron nitride, which is a synthetic material that is second only to diamond in hardness.

4. Grit size: The grit size of the CBN particles in the wheel can vary depending on the specific application.

5. Dressing: Like other grinding wheels, vitrified CBN wheels need to be regularly dressed to maintain their performance. Dressing methods include single point diamond dressers or rotary dressing tools.

Overall,

Moresuperhard vitrified CBN wheels offer a superior tooling solution for machining air-conditioner compressor cylinders, providing excellent performance in terms of precision, durability, and efficiency.

---EDITOR:Alan Wang,Jackie Wang

---POST: Jackie Wang