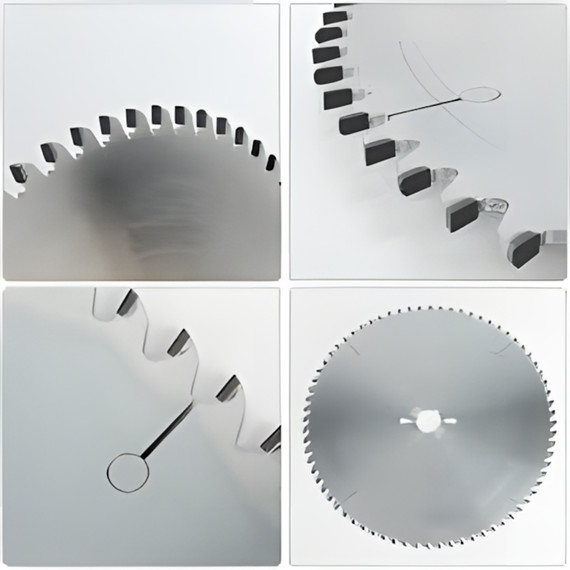

For manufacturers seeking a reliable, high-precision solution for sharpening PCD (Polycrystalline Diamond) circular saw blades, the MX813 PCD Circular Blade EDM Grinding Machine stands out with its unique design, advanced technology, and exceptional performance. Engineered to optimize the top-edge machining of PCD saw blades, this machine integrates innovative features to reduce non-processing time, enhance machining accuracy, and improve the actual application effect of saw blades—making it an indispensable asset for precision processing industries.

Core Technologies & Advantages of MX813 PCD Circular Blade EDM Grinding Machine

The MX813 is built with cutting-edge technologies that address key pain points in PCD saw blade sharpening, delivering tangible value for your production line:

- Concentric Circular Dial Tooth Indexing Technology: Eliminates the need for individual tooth inspection and indexing procedures, significantly reducing non-machining time while boosting machining accuracy—ensuring consistent results across every tooth.

- Central Positioning Clamping: Adopts a unified clamping method for both saw blade grinding and on-site use, minimizing deviations caused by clamping differences and improving the saw blade’s actual working performance.

- Online Rotating Discharge Electrode with Compensation: Equipped with an online rotating device for the discharge electrode, paired with real-time online compensation functionality. This ensures stable processing precision even during long-duration operations.

- 7-Axis AC Servo Drive: Delivers precise, smooth motion control across all axes, supporting complex machining requirements and achieving ultra-high positioning accuracy.

- Comprehensive Safety Configuration: Features an automatic fire extinguisher, providing reliable protection for your equipment and workshop environment.

- User-Friendly Operation: Equipped with a 15-inch LCD display, touch screen + button input, and Chinese-language interface. The Windows Embedded Standard operating system ensures intuitive operation and easy parameter adjustment.

Application Fields of MX813 PCD Circular Blade EDM Grinding Machine

The MX813 PCD Circular Blade EDM Grinding Machine is specifically designed for sharpening PCD circular saw blades used in a wide range of precision processing industries, including:

- Optical glass processing

- Woodworking (high-precision cutting)

- Stone processing (hard material cutting)

- Metal processing (specialty alloy cutting)

- Electronic component manufacturing (precision trimming)

It is ideal for businesses producing or maintaining PCD saw blades that require strict dimensional accuracy, smooth edge finishing, and consistent performance.

Why Choose the MX813?

- Unmatched Precision: Achieves saw blade machining precision ≤0.03 mm and edge roughness ≤Ra0.4 μm, meeting the highest industry standards for precision cutting.

- Efficient Production: Reduces non-processing time via concentric tooth indexing and delivers stable grinding efficiency, ensuring timely completion of production orders.

- Versatile Compatibility: Accommodates saw blades from Ф110~Ф800 mm with customizable inner diameters, supporting diverse application scenarios.

- Reliable & Durable: Built with high-quality components, 7-axis servo drive, and safety features, ensuring long-term stable operation and low maintenance costs.

- User-Centric Design: Intuitive interface, flexible operation modes, and unified clamping design simplify workflow and reduce operator training time.

Get in Touch

Elevate your PCD saw blade sharpening process with the MX813 PCD Circular Blade EDM Grinding Machine. Whether you need standard configurations or custom solutions for special-sized saw blades, our team is ready to assist. Contact us today for a detailed quotation, technical consultation, or on-site demonstration—let’s power your precision manufacturing journey together!