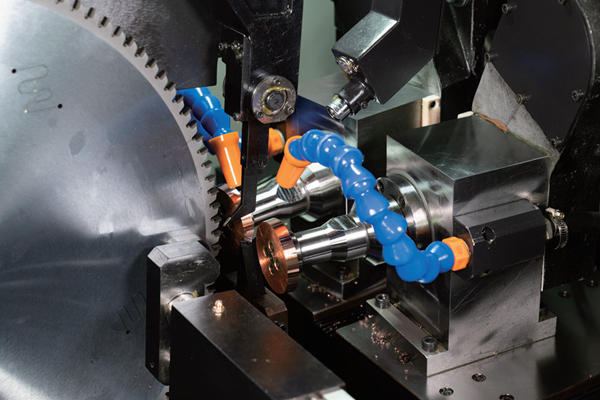

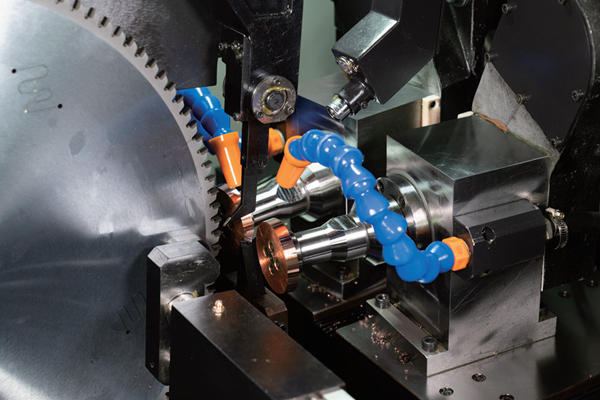

MX810 and MF821 are dedicated saw blade processing machines. They are two machines with unique design concepts for PCD saw blade grinding and regrinding.

★The machine tool adopts multi-axis numerical control, stepless speed regulation grinding head and servo gear shifting mechanism, which can realize the electrical discharge processing of PCD circular saw blades with various tooth shapes.

★The MX810 and MF821 PCD saw blade electrical discharge grinding machine is mainly designed for grinding the top, chamfering and double-sided grinding of various conventional saw blades with diameters <400mm

Features of More Superhard excellent PCD saw blade EDM Grinding Machine:

Features of More Superhard excellent PCD saw blade EDM Grinding Machine:

★Self-developed control system

The machine tool is controlled by adopting advanced industrial-grade computers, liquid crystal display touch screens, genuine Windows embedded standard operating systems, combined with the self-developed fill-in-the-blank humanized design numerical control software for electrical discharge grinding.

★ Automatic turning compensation

During the processing, the electrode wheel wear can be set in advance, and compensation can be made by turning again during the processing. This can avoid the situation of inaccurate processing accuracy caused by electrode wear during the processing. All operation processes are not only convenient and fast, but also effectively improve the accuracy of saw blade manufacturing. During the multi-tooth tool processing, it can be automatically completed in one go without human intervention.

★Numerical control gear shifting

The CNC gear setting adopts the concentric circle gear setting technology, which significantly reduces non-processing time, improves high precision, expands the processing range of the saw blade, conforms to the processing principle of grinding and using together, and makes the practical effect of the saw blade better.

★Powerful standard configuration and control system:

●High-power rigid precision grinding head

●Pneumatic presser feet ensure stable processing of saw blades. The saw blade clamping adopts a reducer sleeve, which is simple and economical

●The manual/automatic slide table expands the application space of the machine tool, enabling it to process both small and large saw blades and achieve the function of section cutting during the turning process, thus avoiding short circuits in copper cutting.

●The pneumatic system ensures the stability of the processing process, and the transmission system is equipped with Panasonic AC servo motors.

●PMI precision ball screws and precision linear guides to ensure precise positioning.

●Self-lubrication system

●Use low-cost red copper electrode wheels.

●The idle running speed and processing speed can be adaptively adjusted for rapid advance and retreat, and the motion positioning is precise and reliable

●In one cycle, the processing of the teeth can be interrupted, with one clamping and one shaping process.

★Quick and convenient operation

●The tooth profile library is rich and has an expansion function. The grinding is simple, minimizing the operational difficulty to the greatest extent. There is no need to adjust the tooth spacing and basic thickness, and it has the function of skipping teeth processing.

●Power supply and intelligent discharge gap control system

●The PCD dedicated equal energy pulse generator with innovative ideas strictly controls the actual pulse width and pulse gap of discharge, reduces electrode loss, and makes the processed surface uniform and consistent.

Combined with the intelligent discharge gap control system, the pulse utilization rate can be improved to the best state, further enhancing processing efficiency, accuracy and surface finish. During the processing, users can perform numerical control programming based on their actual needs. Once the automatic processing begins, the machine tool can automatically process according to the parameters and depths of rough, medium and finish machining set by the operator.