External cylindrical grinding is the precision finishing of the external surface of a part. Conventional cylindrical grinding machines are designed for the grinding of workpieces in individual as well as small and large series production operations. It is suitable for use in any industry where precise small components are manufactured. Operation is very simple and the machine can be reset very quickly.

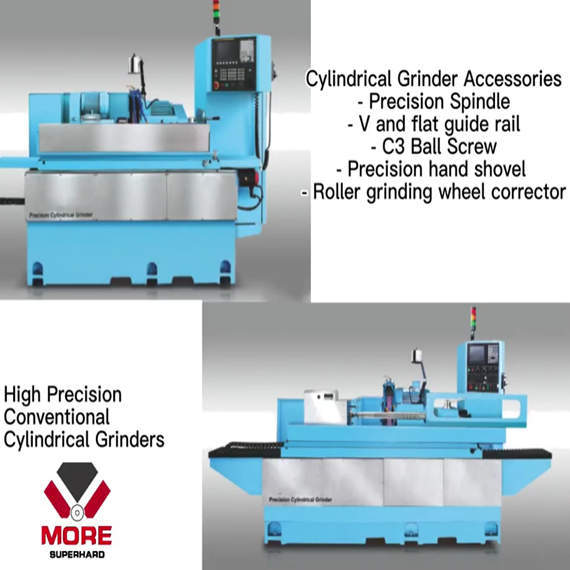

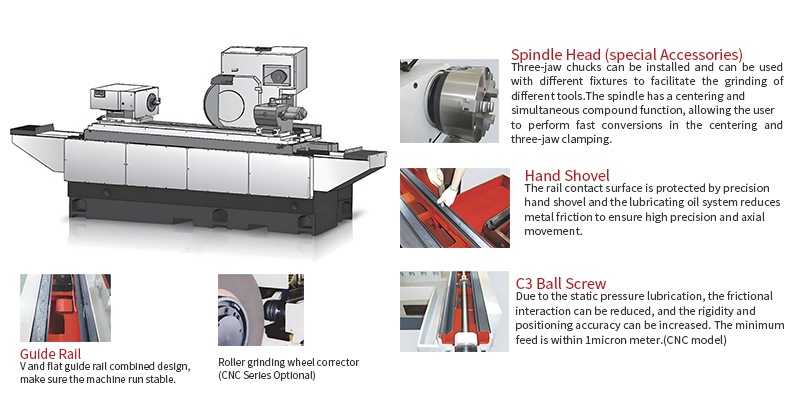

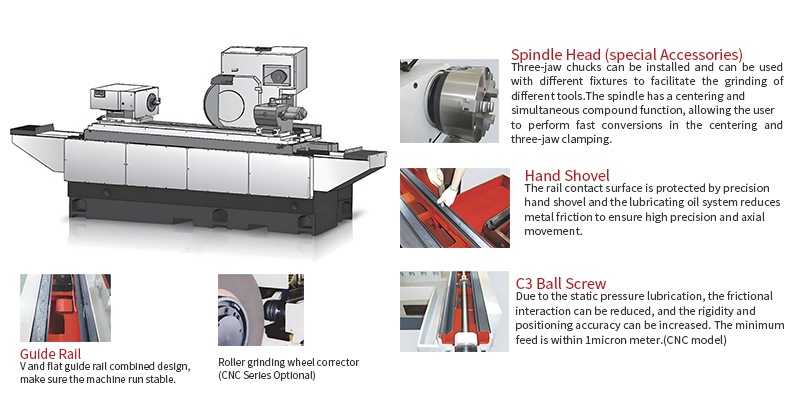

Cylindrical Grinder Standard Accessories

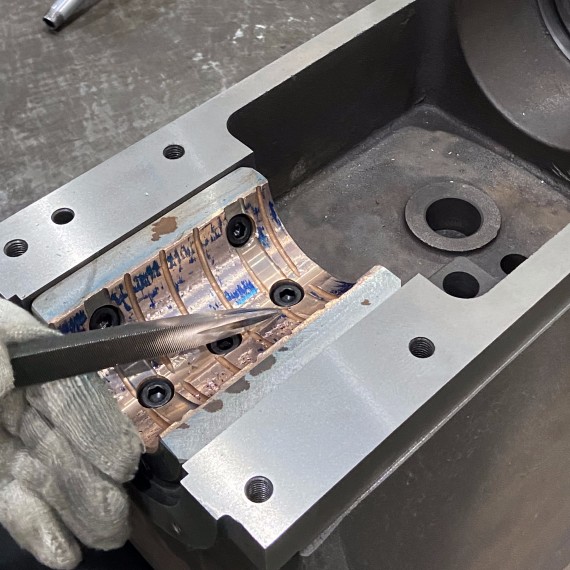

New Design Concept Of Machine Structure

New Design Concept Of Machine Structure

The frame structure is made of Meehanite cast iron and has a low center of gravity design.With the latest finite element computer-aided analysis, the rigid design is above 108N / m and the lowest natural frequency is designed above 150Hz. This outstanding structural design makes the machine fully shock-proof and shock-absorbing, ensuring its high rigidity and maximum damping performance, thus extending the life of the machine.

Operating Plate Displacement And Feed Mode

The left and right displacement of the operating plate and the grinding wheel head are all manually operated.The operating plate is driven by the oil pressure, and the grinding wheel head is fed manually The operating plate is driven by the oil pressure, the grinding wheel head is fast forwarded and fast-returned, and the feed is manually operated.The operating plate is driven by the hydraulic pressure, the grinding wheel head is fast forwarded and fast-returned, and the feed is automatically operated.Install automatic positioning device.

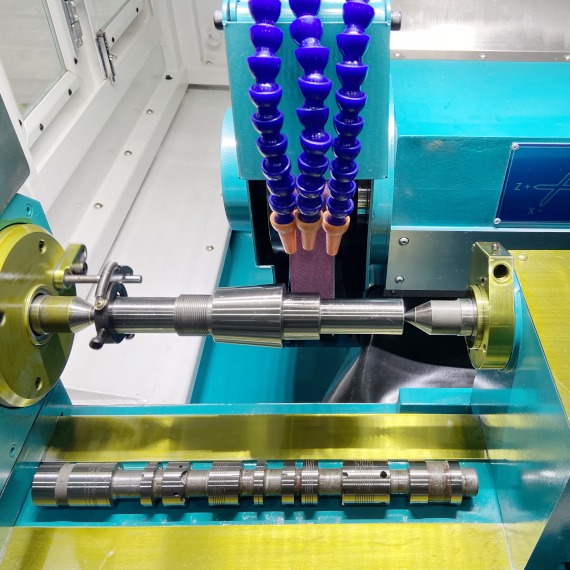

Cylindrical Grinding Method

A Straight Grinding

A Straight Grinding

In small production, the automatic feed is combined with the non-sparking timer for good grinding quality. In the case of mass production, the automatic outer diameter measuring device (special accessory) is installed to provide the best output and grinding effect (CNC model)

B Cross-grinding

The automatic intermittent feed and hydraulically driven table allow the workpiece to be effectively ground.

C Face Grinding

Remove the rotating cover of the working spindle head and replace it with a three-jaw or four-jawchuck. Change the position of the positioning tip to rotate the chuck and fix it at 90 degrees for end grinding.

D Shoulder Grinding

When the outer diameter of the workpiece and its shoulder need to be finished once, the workpieceis supported by two centerings and the grinding wheel is modified to the right of the grinding wheel head and rotated at an angle to grind.

E Slope Grinding

The work object can be supported by the chuck or the two cente rings, and the work bench and the grinding wheel head can be rotated and adjusted easily

F Inner Diameter Grinding

Grinding the inner diameter of the inner diameter grinding attachment (special accessory), as long as the inner diameter grinding spindle is pulled down and fixed in the grinding position, it can be ground.

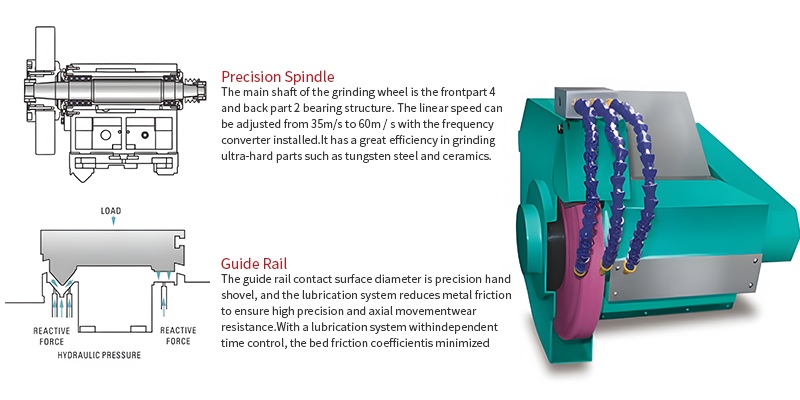

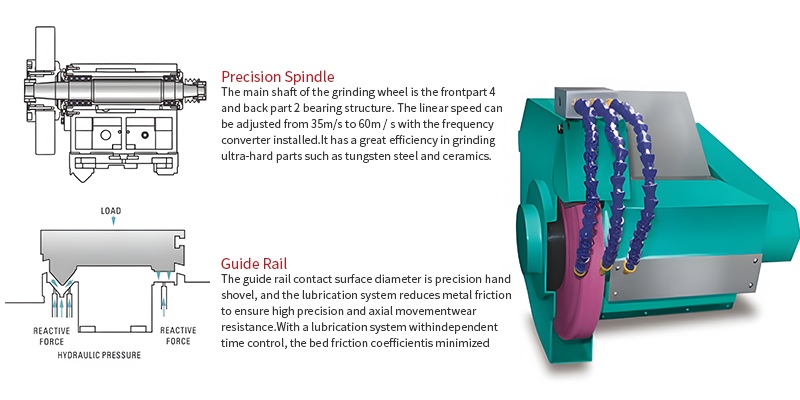

Specially Designed Grinding Wheel Spindle

The line speed can be adjusted from 35m/s to 60m/s in the case of adding a frequency converter, It has a great efficiency in grinding ultra-hard parts such as tungsten steel and ceramics