Machine Overview of High Speed Grinding Wheels Machine

The M400D-KW is a dedicated high-performance grinding wheel machine engineered with a focus on safety, structural integrity, and operational stability. Its rigid construction is designed to endure dynamic and impact loading conditions, optimized through Finite. Element Analysis (FEA). Proven across thousands of installations, the M400D-KW offers. superior durability, reliability, and extended service life.

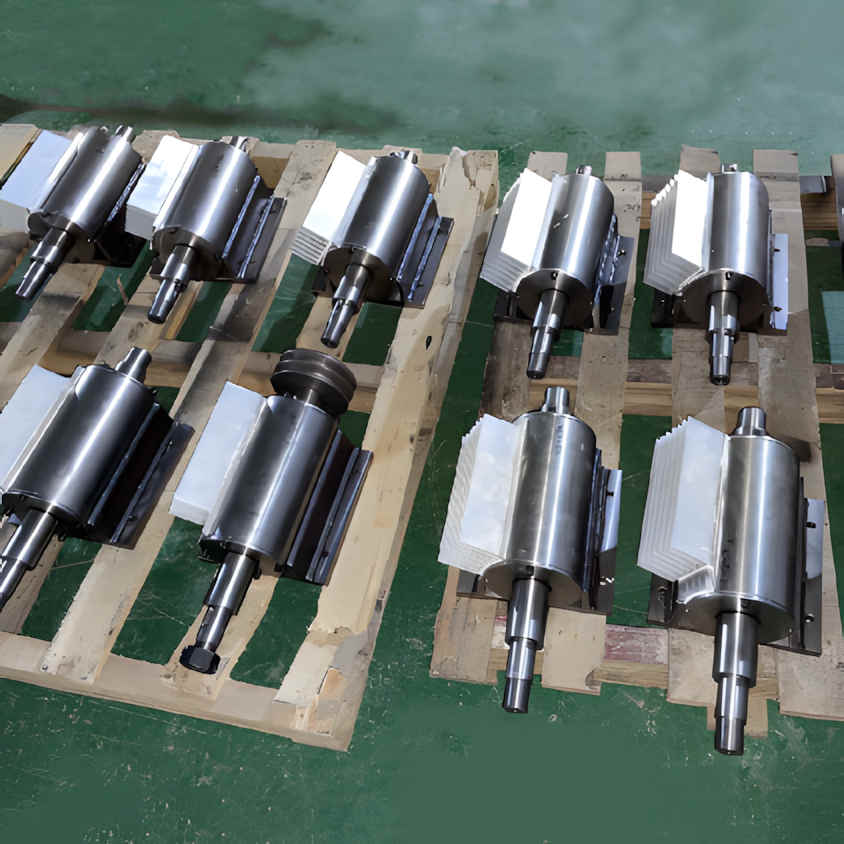

Manufacturing & Quality Assurance

Key Component Selection of High Speed Grinding Wheels Machine

• All critical components are sourced from industry-leading manufacturers.

• Mechanical components are CNC machined with supplier partnerships exceeding five years, ensuring consistent quality and supply reliability.

Quality Control Protocols

Quality Control Protocols

• Spindle Runout Tolerance: ≤ 0.02 mm.

• End-to-end Quality Tracking:

• Incoming material inspection

• In-process dimensional and torque verification

• Fastener torque marking and secondary validation

• Final system checks before shipment

Electrical & Environmental Safety

• All electrical assemblies are hermetically sealed to prevent dust ingress.

• Cables routed through protected grommets and sleeves to ensure safe, long-term operation in dust-intensive environments.

*Note: To date, over several thousand units have been deployed without a single reported after-sales issue.*

Model Variants of High Speed Grinding Wheels Machine

A. Single-Station Grinding Machine (Mineral Composite Base)

This model utilizes a one-piece mineral composite cast base, a proprietary technology developed and patented by our company.

• Exceptional Vibration Damping:

Offers 10× the vibration absorption of conventional cast iron, reducing grinding-induced vibration. Improves operator comfort and productivity, while extending tool life by 20–40% and reducing acoustic emissions.

• Thermal Stability:

With thermal expansion resistance 30× greater than cast iron, geometric accuracy is preserved under thermal load, ensuring dimensional precision and process stability.

• Superior Corrosion Resistance:

Resilient to aggressive industrial environments.

• High-Temperature Operation:

Equipped with integrated heat dissipation modules and forced air-cooling spindle systems.

B. Dual-Station Grinding Machine

• Designed with a single-motor, dual-spindle configuration, enabling two simultaneous workstations from one machine.

• Optimal for light-to-medium duty grinding operations, significantly reducing equipment cost per workstation.

• Constructed using heavy-duty welded steel plates, with a total machine weight of 500 kg.

• Demonstrates high stability, efficiency, and cost-effectiveness in continuous industrial use.

Compatible Grinding Wheels:

Vacuum Brazed Diamond Grinding Wheels

▶ High efficiency

▶ Longer life time than Resin Bond Tools

▶ Single layer of fully exposed diamond fused with nickel at high temperatures and sharp cutting

▶ Never need dressing