What are the applications of vitrified diamond grinding wheels?

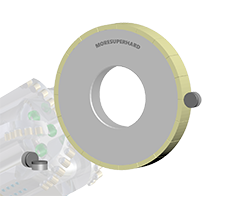

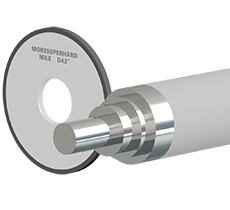

♦ For tungsten carbide workpieces

♦ Steel based tungsten carbide coating workpiece

♦ Non-metallic materials semi-finishing grinding and finishing grinding, etc.

After constant adjustment of formula and technology we finally successfully developed the first vitrified diamond grinding wheel for thermal spraying coating industry.

What are the advantages of vitrified diamond grinding wheels?

What are the advantages of vitrified diamond grinding wheels?

♦ The bonding strength of vitrified bond to grinding is better than resin bond

♦ After customized diamond grinding tools with higher diamond concentration, it is less heat and jam generate in grinding

♦ High grinding efficiency

♦ Very sharp grinding

♦ Long lifespan and easy to dress

In terms of the shaping and dressing of the abrasive tools, it is relatively easy to operate (by using diamond dressing tools, to improve work efficiency and save the time of disassembly of the grinding wheel). It is generally used for semi-finishing grinding, finishing grinding, and forming grinding with large contact surface, etc. Therefore, vitrified bond is a kind of bond that is increasingly widely used until now.

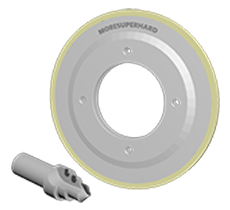

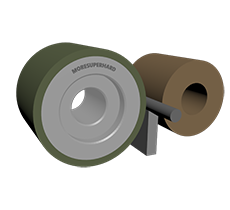

Resin Bond Grinding Wheel is also mainly used in thermal spraying coating process

.jpg)

What are the essential process to make a vitrified diamond grinding wheels?

1. Ingredients. Mixing abrasive and bonding agent,

2. Pressing. Put into the mold and add wetting agent to press,

3. Sintering. Melt the bond and solidify the diamond to reinforce the abrasive layer,

4. Matching the substrate. Turning and trimming the substrate to fit the abrasive layer,

5. Bonding. Use glue to bond the abrasive layer to the matched substrate, place,

6. Dressing the grinding wheel by grinding to reduce the tolerance of shape and position,

7. Marking.

All the grinding wheels delivered to our customers have gone through these steps above. Moresuperhard expects to bring you quality product experience through our strict production control!

.jpg)

.jpg)

.jpg)

.jpg)