Introduction of Customer Case of Electroplated Diamond Hubless Dicing Blades for LED and IC Epiwafers:

In the world of LED and IC (Integrated Circuit) manufacturing, precise dicing blades play a critical role in achieving superior cutting performance and maximizing yields. One of Moresuperhard's customer, a leading semiconductor manufacturer, recently partnered with our company to optimize their dicing process for dice LED and IC epiwafers.

Challenges When Dicing LED and IC Epiwafers:

The customer faced several challenges in their dicing operations. Conventional dicing blades were limited in their ability to deliver the precision and efficiency required to meet the customer's stringent quality standards. Furthermore, the traditional hub-based dicing blades encountered issues with excessive chipping, low cutting speeds, and reduced overall productivity. These challenges necessitated an innovative and reliable solution to optimize their dicing process.

Solution of Electroplated Diamond Hubless Dicing Blades for LED and IC Epiwafers:

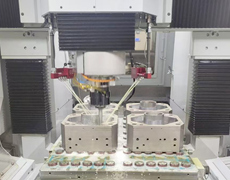

To address these challenges, our company introduced the cutting-edge

Electroplated Diamond Hubless Dicing Blades, specifically engineered to cater to the customer's LED and IC epiwafer dicing needs. The hubless design, combined with the exceptional cutting performance of electroplated diamond, promised significant improvements in both precision and efficiency.

Details of Customer Case in LED and IC Epiwafers Dicing Industry:

Workpiece: LED and IC epitaxial wafer (LED substrate is sapphire and IC substrate is silicon)

Workpiece size: 8-inch wafer X thickness about 300 microns

Scribing machine: HAD1610 dicing machine (Shenyang Hanwei Technology Co., Ltd.)

Granularity:

Granularity: 4000#

Size: D55.55xH19.05, 12A2 35x640-4000-70M

Electroplated Diamond Hubless Dicing Blades Processing Results:

Upon implementing the Electroplated Diamond Hubless Dicing Blades, the customer experienced a transformational impact on their dicing operations. The precision and accuracy achieved by these blades surpassed the customer's expectations, significantly reducing chipping and enhancing the overall quality of the diced LED and IC epiwafers. The hubless design eliminated the need for a flange or hub, allowing for increased contact area and improved stability during cutting. This resulted in higher cutting speeds, reduced vibrations, and enhanced productivity.

Furthermore, the advanced electroplated diamond technology showcased remarkable durability, extending the lifespan of the dicing blades and reducing the frequency of blade replacements. This not only optimized operational costs but also minimized downtime, allowing for uninterrupted manufacturing processes.

Moresuperhard Summary:

The successful collaboration between our company and the semiconductor manufacturer highlighted the transformative potential of

Electroplated Diamond Hubless Dicing Blades in dice LED and IC epiwafer manufacturing. Through improved precision, efficiency, and extended blade lifespan, our customer achieved enhanced yields, reduced costs, and streamlined their dicing operations. The customer can now confidently deliver superior LED and IC products to meet the growing market demands.

By staying at the forefront of dicing blade technology, our company continues to empower semiconductor manufacturers to overcome challenges, elevate their dicing processes, and achieve excellence in LED and IC production.

---EDITOR: Anna Wang,Jackie Wang

---POST: Jackie Wang