In today's competitive manufacturing landscape, maximizing the versatility of existing machine tools is key. Our latest case study demonstrates how diamond and CBN grinding wheels can transform a standard 3-axis milling machine into a high-performance grinding workstation—enabling precision surface grinding of hardened materials without investing in dedicated grinding equipment.

Technical Overview

-

Machine Used: 3-axis milling machine

-

Grinding Wheel: Resin bond CBN wheel (6A2 125×10×10)

-

Workpiece Material: Hardox 600 steel, hardened to 60HRC

-

Plate Dimensions: 600×1000×20 mm

Key Performance Highlights

✅ High-Speed Operation – Wheel speed up to 50 m/s, grinding feed rate up to 15,000 mm/min

✅ Ultra-Precision Grinding – Minimum infeed as low as 0.001 mm per pass

✅ Material Versatility – Effectively grinds hardened steels, tool steels, and other difficult-to-machine materials

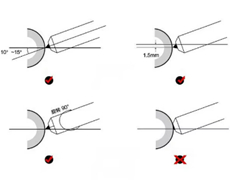

✅ Easy Integration – No mechanical modifications required; wheels can be dressed in-place using a soft steel block (St37)

Why Choose Our Wheels for Milling-Based Grinding?

While milling machines may lack the rigidity and power of dedicated grinders, our specially formulated resin-bond CBN wheels deliver exceptional cutting sharpness and wear resistance. Pre-dressing the wheel ensures consistent performance and extended tool life, making this an economical and efficient solution for shops looking to expand their grinding capabilities.

Applications

-

Surface grinding of hardened plates, molds, and dies

-

Finishing of wear-resistant components (e.g., Hardox, tool steels)

-

Pre-grinding and finishing in tool rooms and repair workshops

Ready to Enhance Your Milling Machine's Capabilities?

Upgrade your milling operations with our high-performance diamond and CBN wheels. Contact our technical team to discuss your application and receive a tailored grinding solution.

Contact Us:

Email: [email protected]

Whatsapp: +8619900915906

https://www.mogrinding.com/