1. Features of Crankshaft Grinder: High precision, high rigidity, high efficiency, mass production stability

Used in aviation, medical, hydraulic, mold, high-end automobile manufacturing, robot reducer and other industries of camshaft, crankshaft and drive shaft, eccentric shaft type workpiece precision grinding, and can achieve a clamping, grinding two eccentric shaft outside diameter and multi-eccentric outside diameter.

The use of advanced numerical control system, the manipulator to achieve automatic clamping, further high efficiency, shorten the production rhythm, but also to avoid the accuracy error of human tooling.

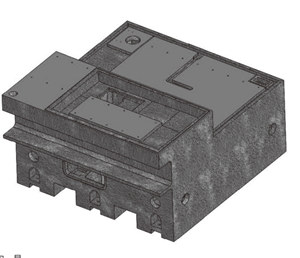

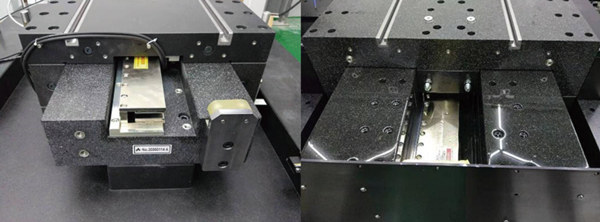

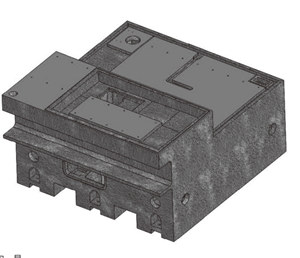

2. High rigidity bed

Bed design:

Integral cast iron bed structure,With excellent heat dissipation and vibration absorption ability, maximize the accuracy of the machine tool retention. Suitable for complex environmental requirements in mass production.

Bed part:

The wheel head frame, workpiece head frame, spindle and all bearing support elements are made of high-grade cast iron or steel material, ensuring a homogeneous, continuous and stable coefficient of thermal expansion between the machine bed and components. Thus providing a more stable working environment

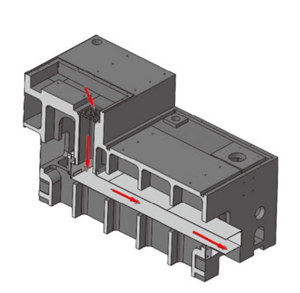

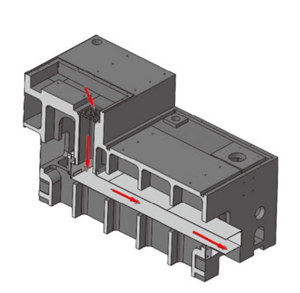

Rapid hollow drainage structure design:

Rapid hollow drainage structure design:

● Unique drainage structure, the grinding area of the body

● work surface is designed with inclined surface and hollow

● drainage structure to form a drainage channel, and the oil sewage slag flows into the embedded

● drainage tank along the drainage outlet, making full use of the internal cavity, so that the grinding coolant is discharged in time

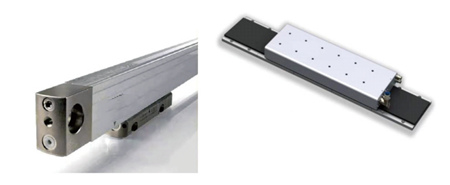

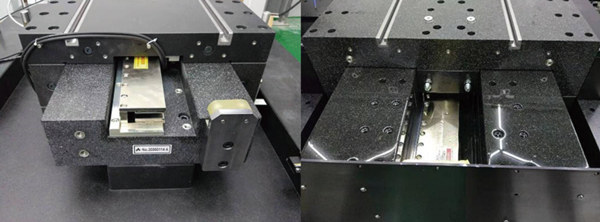

3. Hydrostatic Guide Rail

● Composite material through nitriding, cryogenic treatment, high rigidity

● Shadic linear motor.

● Heidenhain grating ruler.

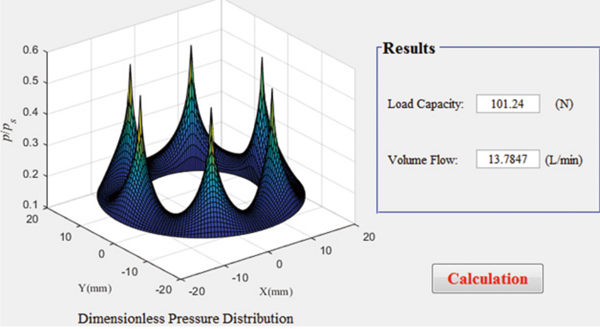

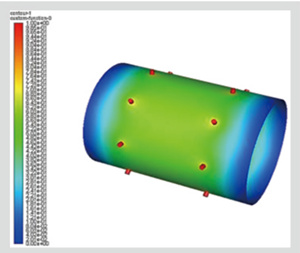

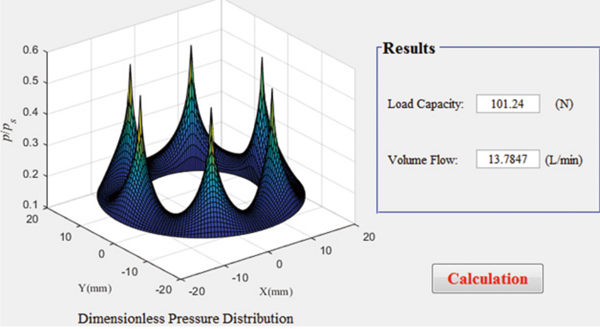

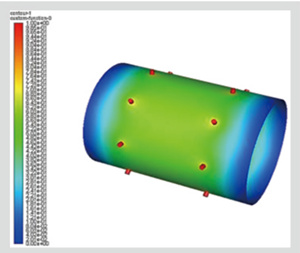

Professional and mature fluid calculation system for accurate calculation of load, rigidity and thermal stability of hydrostatic components

Fluid - solid - thermal - magnetic multi-physical field coupling analysis ability, simulation calculation.

4. Control System

.jpg)

● Graphical software is easy to learn

● Bulk-storage memory

● Multi-wheel data management

● Ethernet , RS232 Interface

● USB and flash card storage

● Background editable

● Remote diagnosis and help

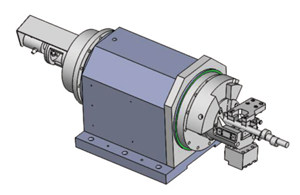

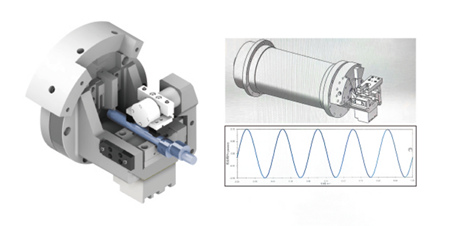

5. Precision Configuration

a. Features:

a. Features:

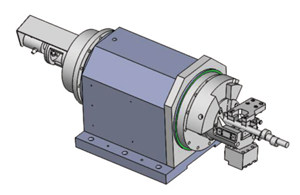

● High precision and high rigidity workpiece electric spindle

● Permanent magnet synchronous motorized spindle.

● Renishaw circular grating ruler and encoder.

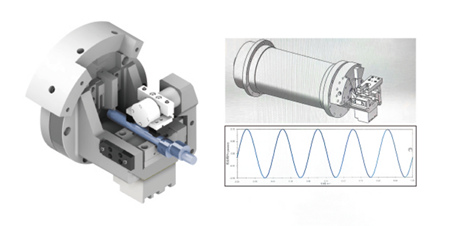

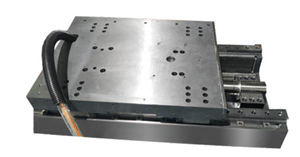

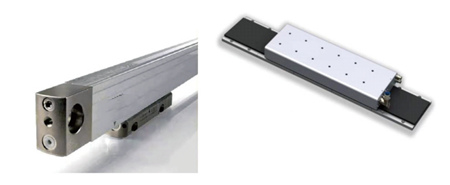

b. X-axis linear motor and grating ruler

c. Z-axis screw feed

Z-axis feed shaft adopts pre-loaded high-precision linear guide rail design, which can withstand loads in all directions. There is a lubricating liquid return channel between the guide rails, and the guide rail moves smoothly, which minimizes the friction coefficient, eliminates the possibility of crawling at low speed, reduces the wear of the guide rail to the greatest extent, increases the service life, and greatly improves the programming accuracy. The C2 class ball screw has excellent accuracy retention.

d. High speed grinding wheel electricity spindle

● Ball screw bearings

● Dynamic balance G1

● 8000RPM

● Run out W0.001

● Internal circulation cooling

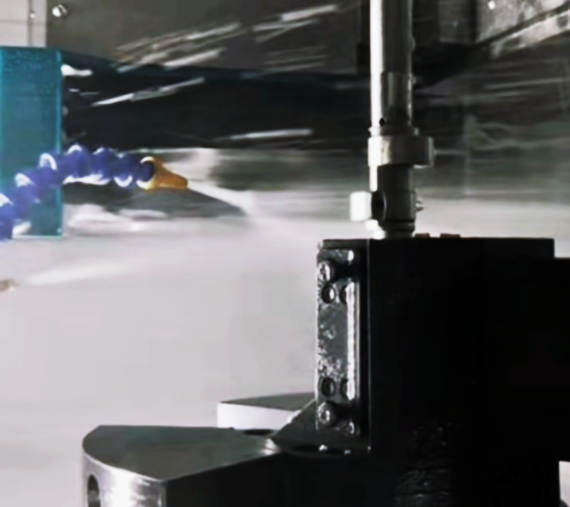

e. Marposs anti-collision system

·online inspection

·Online wheel dressing

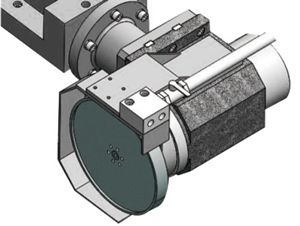

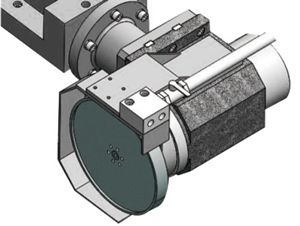

f. Universal type side pressing fixture

The workpiece fixture design has been balanced simulation optimization, reducing the impact of the fixture on the machining accuracy, the fixture is compatible with the characteristics of conventional crankshaft parts, high versatility, floating pressing mechanism, greatly reducing the error brought by pressing, thus improving the pass rate and machining accuracy

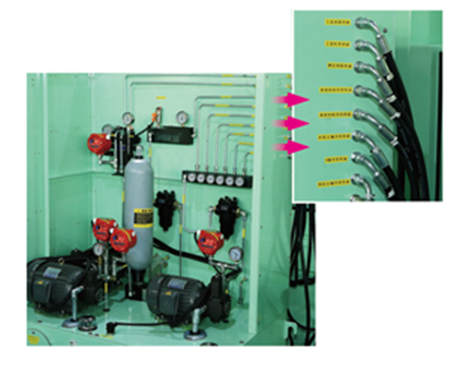

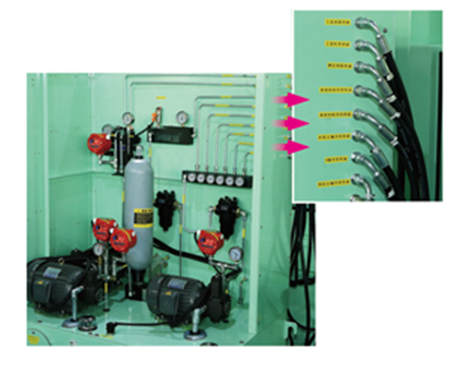

6. Individual Oil Coolers

● Refrigerant gas leakage detection and alarm function

● Oil temperature warning function

● Automatic adjustment function

● Component maintenance reminder function

.jpg)

a. Features:

a. Features:

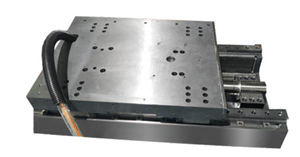

Z-axis feed shaft adopts pre-loaded high-precision linear guide rail design, which can withstand loads in all directions. There is a lubricating liquid return channel between the guide rails, and the guide rail moves smoothly, which minimizes the friction coefficient, eliminates the possibility of crawling at low speed, reduces the wear of the guide rail to the greatest extent, increases the service life, and greatly improves the programming accuracy. The C2 class ball screw has excellent accuracy retention.

Z-axis feed shaft adopts pre-loaded high-precision linear guide rail design, which can withstand loads in all directions. There is a lubricating liquid return channel between the guide rails, and the guide rail moves smoothly, which minimizes the friction coefficient, eliminates the possibility of crawling at low speed, reduces the wear of the guide rail to the greatest extent, increases the service life, and greatly improves the programming accuracy. The C2 class ball screw has excellent accuracy retention. ● Ball screw bearings

● Ball screw bearings