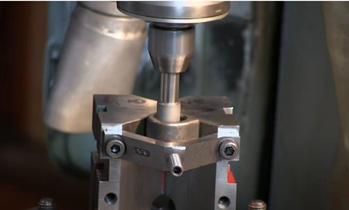

Jig grinding machine is a high precision grinding machine developed for the purpose of eliminating the deformation of the heat treatment of materials, with precision coordinate positioning device.

Jig grinding mandrel can grind holes with high position accuracy and dimensional accuracy, as well as a variety of precise contour shapes. Usually processing the workpiece's inner hole, non-circle, periphery (can provide continuous path contour processing), cone, cavity, etc. It can carry out complex 2D/ 3D parts processing.

Three kinds of Jig grinding:

1. Radial feed grinding: Grinding by using the circumferential surface of the grinding wheel. When feeding, the grinding wheel moves a little relative to the workpiece along the direction of the eccentric radius. High dimensional accuracy and low roughness can be obtained when using ceramic bonded grinding wheel.

2. Plunge grinding: Using the end face of the grinding wheel, also known as end face grinding, grinding wheel along the axial feed.

3. Insert grinding: As the wheel moves rapidly up and down, grind around the contour of the part being ground. It is characterized by a larger cutting depth and less heat

.

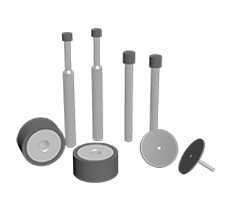

Application of Jig grinding wheel:

Jig grinding mandrel be used in motor molds, lead frame molds, semiconductor molding molds and other fields, can also be used in CNC machining center, small internal grinding machine, scientific research, experimental grinding machine, etc.

Jig CBN grinding mandrel for I.D. , high speed steels and heat treated steel pieces, Jig diamond grinding mandrel for I.D. and Jig Grinding of Carbides and Non-Metallics.

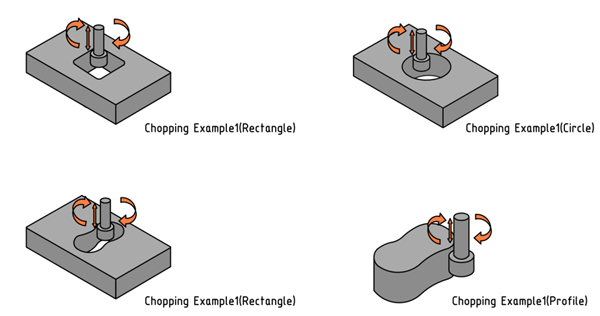

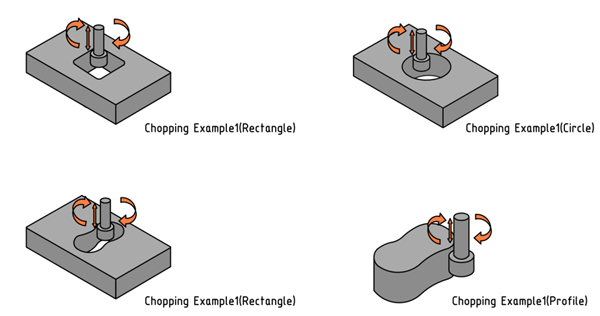

Typical shapes of CNC Jig grinding machine grinding :

1. Round hole grinding (straight hole, small hole, cone hole, blind hole, etc.)

2. Face grinding

3. Square hole grinding

4. Arc grinding

5. Groove grinding

6. Spherical grinding

7. Spherical and external contour grinding

.jpg)

.jpg)