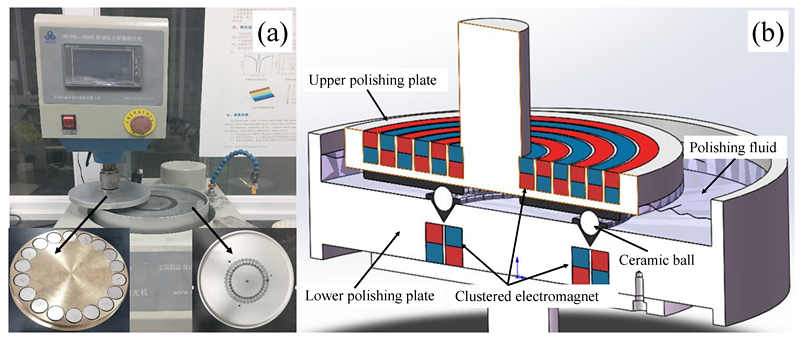

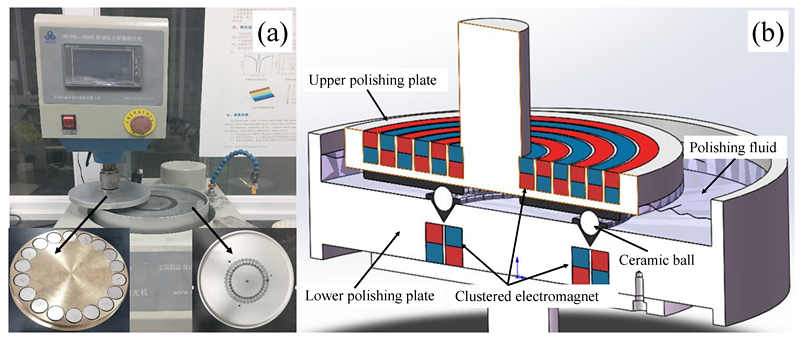

What problems will occur in the polishing process of high precision ceramic ballWhy we choose ceramic balls?

The development of industrial technology on machine tools and instruments and equipment precision, speed, reliability and other performance requirements are increasingly high. Compared with the traditional bearing steel, alumina, silicon nitride, silicon carbide, etc., ceramic ball bearings have a long service life, high speed, good overall accuracy and rigidity, good thermal stability performance and non-magnetic and other more excellent comprehensive performance. So it has a very broad application prospect.

With the progress of science and technology, ceramics, alloys, and other materials are more and more widely used, and people's requirements for the surface polishing accuracy of these materials are also increasingly high.

However, ceramic materials have high hardness and poor toughness. Especially for spherical materials, the production and processing process is more complex, and it is easy to produce scratches and nibbles when polishing them, and the surface finish and roughness of the material are difficult to reach the desired level, which affects the final use effect. At present, the polishing of ceramic materials mainly uses diamond abrasive, and more related technologies have appeared on the market. Diamond is the hardest substance known in nature, and its high hardness and good wear resistance can be widely used for cutting, grinding, drilling, polishing, etc. It is the ideal raw material for grinding and polishing optical crystals, ceramics, super-hard alloys and other high-hardness materials.

What problems will occur in the polishing process of high-precision ceramic balls?

At present, the last fine polishing consumables used for high-precision ceramic balls generally have the following problems.

1. most of the existing technologies use oil-based systems, which are not easy to clean after polishing.

2. some diamond grinding solutions have a too high concentration of abrasives, which brings higher costs.

3. some use a lower concentration of micronized powder, which has minimal improvement in adhesion.

4. not easy to achieve the polishing effect of G3 grade silicon nitride ceramic ball and the surface of the ball as a mirror surface.

How to solve these problems when polishing high-precision ceramic balls?

It becomes more and more important to design a suitable liquid formulation to improve the adhesion of

polishing liquid on the surface of ceramic balls. Due to the use of lower micron powder concentration, the process of collision between particles during polishing is prone to the gnawing, so it is necessary to design a suitable liquid formulation to increase the buffering effect of ceramic ball collision, thus reducing gnawing. In addition, a suitable liquid formulation makes diamond micro powder with good suspension, which can make it fully participate in grinding and polishing, and the powder content is greatly reduced while the grinding and polishing efficiency is increased.

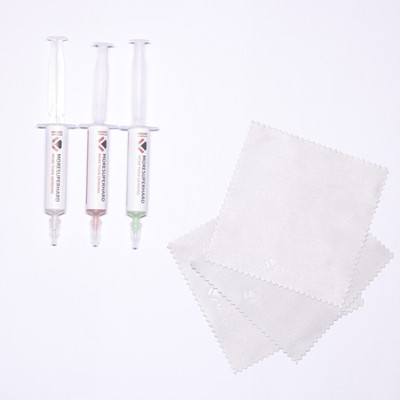

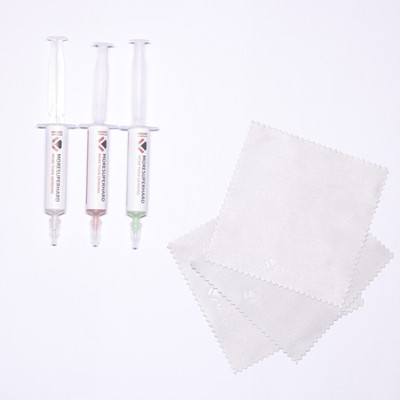

Diamond Polishing Paste, Diamond Compound is divided into water-soluble polishing paste and oil-soluble polishing paste

Package: injector, bag or box

Spect: 5g、10g、30g、100g and so on

Diamond size of polishing pase: W0.25 W0.5 W1 W1.5 W2.5 W3.5 W5 W7 W10 W14 W20 W28 W40

Moresuperhard can also provide special products according to users' requirement and we can also provide CBN polishing paste, CBN compound