What is a compound bonder?

Vitrified, resins, and metal binders all have certain characteristics, such as good self sharpening performance of ceramic binders, good impact resistance of resin binders, and high strength of metal binders. However, there are also corresponding defects, such as high brittleness of ceramic binders, poor wear resistance of resin binders, and poor self sharpening performance of metal binders. Therefore, compound binders learn from each other's strengths and weaknesses, striving to achieve the best comprehensive performance, have increasingly become a research hotspot, and are gradually being applied in production. Currently, the most researched or applied compound binders mainly include metal ceramic compound binders (metal as the main body), ceramic metal compound binders (ceramic as the main body), and resin metal compound binders (resin as the main body). Poor heat resistance, metal resin (metal body) Ceramic resin (ceramic body) compound binders are not the research direction.

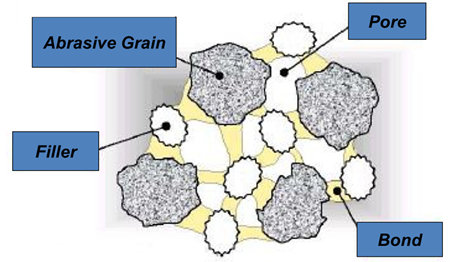

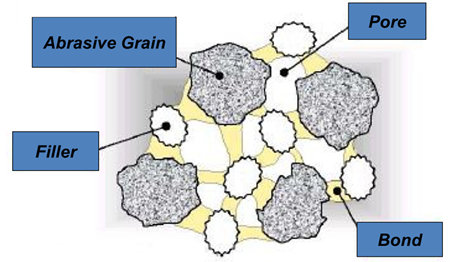

In fact, adding some Al2O3, SiC, etc. to metal binders, and adding some Cu powder, Cu Sn alloy powder, graphite, etc. to resin binders are common practices in the industry. They only refer to additives as "fillers", which can also be referred to as compound binders.

How do we choose binders when choosing grinding wheels?

How do we choose binders when choosing grinding wheels?

The bonding of resin and metal bonding agents to abrasives is generally considered as mechanical embedding force, but due to the lack or absence of pores, the strength of the grinding wheel is relatively high (although metal bonding grinding wheels have a saying that "strong carbide forming elements will react with diamonds to form carbides, forming chemical bonding", it is only theoretical and there is no strong experimental observation of the existence of carbides). Ceramic bonding agents can form chemical bonding with abrasives, but due to the brittleness of ceramic bonding agents, abrasive shedding is also more severe under high impact loads.

The selection of binders, on the one hand, is the selection of types of binders. Due to the advancement of product technology, in many processing fields, resin bonded grinding wheels can be processed, ceramic bonded grinding wheels can also be processed, or metal bonded grinding wheels can also be processed. How to optimize the grinding plan is a concern for industry professionals. On the other hand, it is the selection of binder systems. For example, there are many systems or types of binders for each type, and how to select or prepare binders for specific grinding requirements is also a test of skill.

Therefore, industry technicians should take the research of binders as the basic research and core technology breakthrough of enterprises:

a. The following viewpoints are not advisable:

A type of ceramic binder is omnipotent, such as using the same binder for internal grinding, external grinding, and end grinding, attempting to meet each application by adjusting the binder ratio. Relying on purchasing binders, there is no digestion and absorption, let alone basic research, and it will only be subject to human constraints, slow development, let alone innovation and breakthroughs.

b. Why can't one ceramic binder be used all over?

Internal grinding, cylindrical grinding, and end face grinding are three different forms of grinding, with different grinding mechanisms and diverse processing applications. Even if the ceramic bond has good performance, high strength, and good toughness, it is difficult to achieve the usage requirements solely by adjusting the grinding wheel formula.

Even if high-performance ceramic bonding agents are used to produce grinding wheel products that meet the usage requirements, and regardless of the previous testing times, if there are changes in the material and processing requirements of the workpiece processed by the customer, the grinding wheel formula is likely to become unusable again.

We all know that a customer cannot give you too many testing opportunities, and if you fail to meet the requirements several times, you will be eliminated. Therefore, it is necessary to establish your own bonding system, which has many standards, such as porosity or strength.